Brass is mostly an alloy made from copper and zinc. Sometimes, there are small amounts of lead, tin, or nickel in it. The mix of these elements changes how brass acts when you machine it. For example, if you use a cnc machine on brass, the right mix makes it easier and faster to work with. The table below shows the usual percentage range for copper and zinc in brass:

Component | Percentage Range |

|---|---|

Copper | 60% to 90% |

Zinc | 10% to 40% |

Lead helps make brass easier to machine. This is why people like to use brass for high-quality parts. Brass cnc machining gives you strong and accurate parts with good quality. You can trust brass machining for parts that need to be strong and made quickly.

Brass is mostly made from copper and zinc. The amount of each changes how brass looks and works.

Picking the right brass type is important. C360 is good for easy cutting. C260 is better for bending. This helps get better results when using CNC machines.

Brass is easy to shape and cut. It does not rust easily. It is strong. These things make brass great for many uses. It is used in cars and plumbing.

Adding things like lead, tin, or nickel can make brass better. These extras help brass last longer and be easier to work with.

Knowing what is in brass helps you choose the best kind. This means your project will turn out well and not cost too much.

You find that brass is mostly made from copper and zinc. These two metals give brass its main features. Copper gives brass a reddish color and helps with electrical conductivity. Zinc makes brass stronger and more elastic. When you change the amount of copper and zinc, you change how brass looks and works. If you use more copper, brass looks golden and is easier to bend. If you add more zinc, brass becomes brighter yellow or even grey-silver. The strength of brass goes up as you add more zinc, but it can become less resistant to corrosion. This is important when you choose brass for cnc machining brass projects because you want the right balance for your part.

Tip: The color of brass changes from reddish to yellow and then to grey-silver as zinc content increases. This helps you pick the right brass for your design.

You sometimes see other elements in brass. Lead is often added to make brass softer and easier for machining. Tin increases strength and hardness, which helps when you need tough parts. Nickel gives brass a silver color and can improve corrosion resistance. Manganese turns brass a warm chocolate-brown. Arsenic helps brass stay stable in certain environments. These extra elements change the properties of brass and help you get the best quality for cnc machining brass.

Lead makes brass easier to machine.

Tin boosts strength and hardness.

Nickel adds a silver color.

Manganese gives a brown shade.

Arsenic improves stability.

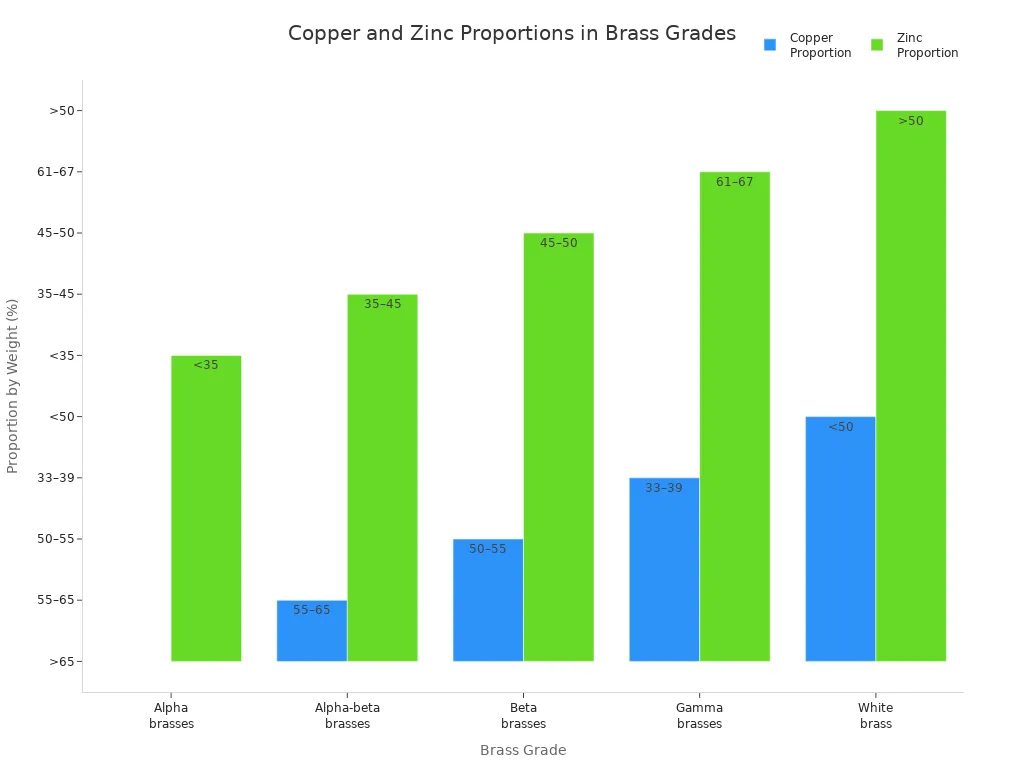

You need to know the proportion ranges of copper and zinc in brass. This helps you choose the right type for cnc machining brass. The table below shows common brass grades and their copper and zinc percentages:

Class | Copper (%) | Zinc (%) | Notes |

|---|---|---|---|

Alpha brasses | > 65 | < 35 | Malleable, golden color, good for cold working |

Alpha-beta brasses | 55–65 | 35–45 | Brighter, suited for hot working |

Beta brasses | 50–55 | 45–50 | Harder, stronger, hot working only |

Gamma brasses | 33–39 | 61–67 | Brittle, special uses |

White brass | < 50 | > 50 | Very brittle, sometimes called nickel silver |

When you select brass for cnc machining, you look at these ranges to match the properties of brass to your needs. High zinc content means more strength, but less ductility. If you want easy machining and high quality, you often choose brass with added lead and a balanced copper-zinc mix. This helps you get the best results in cnc machining brass and cnc brass machining.

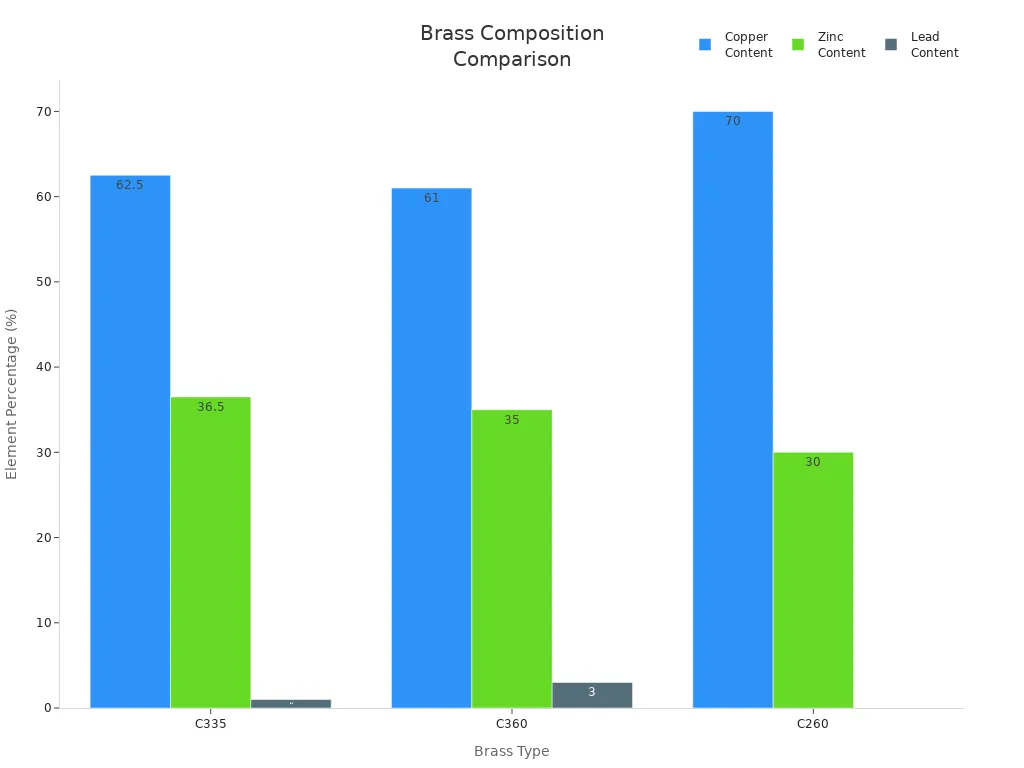

Brass has many grades. Each grade has its own mix and features. You should know these differences before you pick brass for your project. JOC Machinery sells many brass grades for cnc machining and casting. Let’s check out three common brass grades. Their mix changes how easy they are to machine, bend, and resist rust.

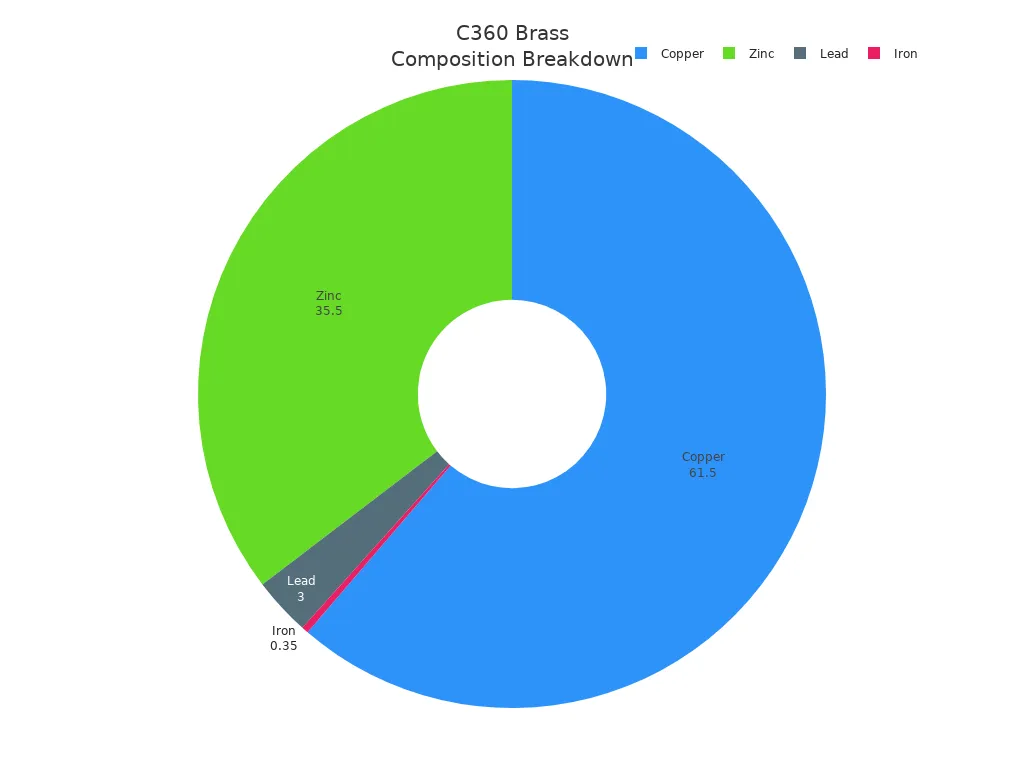

C360 Free-Cutting Brass is a top pick for machining. It has copper (61.5%), zinc (35.5%), and lead (3%). Lead makes this brass simple to cut and shape. You can use cnc machines fast with this grade. This saves time and helps tools last longer. C360 gives smooth surfaces and strong parts. Many people use C360 for gears, valves, and electrical fittings.

Tip: Pick C360 Free-Cutting Brass for quick machining and good results.

C260 Cartridge Brass has about 70% copper and 30% zinc. You see this brass in bullet casings, plumbing, marine parts, and musical tools. The high copper makes it easy to bend and stops rust. You can shape this brass easily. It works well for deep drawing and forming jobs. JOC Machinery gives C260 to many industries needing strong and nice-looking brass.

Application Area | Description |

|---|---|

Ammunition Casings | Strong and resists rust |

Plumbing Fixtures | Lasts long and works well |

Marine Hardware | Stays good in wet places |

Musical Instruments | Great for sound quality |

C335 Free-Machining Brass has 62.5% copper, 36.5% zinc, and 1% lead. It is easy to machine, but not as much as C360. This grade is good for parts needing both strength and easy machining. You can use C335 for fittings, fasteners, and other parts needing quality.

You should match brass properties to your job. Here is a table with main brass features by grade:

Brass Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Electrical Conductivity (% IACS) |

|---|---|---|---|---|---|

C360 | 345-450 | 110-210 | 80-100 | 20-30 | 25-30 |

C260 | 300-550 | 95-250 | 60-85 | 25-40 | 27-35 |

C335 | 350-450 | 120-200 | 75-95 | 18-28 | 26-32 |

C360 is best for easy machining and smooth surfaces.

C260 is great for bending and stopping rust.

C335 gives both easy machining and strength.

When you buy brass from JOC Machinery, you get good quality and help from experts. Our team helps you pick the right brass for your cnc machining, casting, or forging job. You can trust our skill and products to give you the best results.

Brass is a good choice for cnc machining. It is simple to cut and shape. You can drill it easily. This helps you make parts faster. It also saves money. Brass parts are strong and last a long time. They look smooth and nice. The table below shows why brass works well for cnc machining:

Property | Description |

|---|---|

Excellent machinability | Brass is easy to machine, leading to efficient production processes. |

Corrosion resistance | It withstands environmental factors, enhancing the longevity of machined parts. |

Strength | Brass possesses a high degree of strength, making it durable for various applications. |

Ductility | The material can be easily shaped without breaking, allowing for intricate designs. |

Malleability | Brass can be deformed under compressive stress, facilitating complex machining tasks. |

Low friction | This results in minimal heat generation during machining, improving efficiency. |

Dimensional stability | Brass maintains tight tolerances due to its low coefficient of thermal expansion. |

Ease of cutting | The softness of brass allows for easier cutting compared to harder materials, reducing tool wear. |

Cnc machining brass gives you good results. You can make simple or complex parts. JOC Machinery uses advanced machines for brass. We make high-quality brass parts for many industries.

To get good brass cnc machining, pick the right brass grade. You also need the best machining process. C360 and C260 are top choices for cnc machining brass. They are easy to machine and give precise parts. Think about your design and how smooth you want the surface. C360 is great for fittings and gears. C260 is better for deep-drawn parts.

Tip: Always match the brass grade to your application for the best quality and durability.

JOC Machinery can help you choose the right brass. We know how to machine pump and valve parts. We also make bearings, gears, and custom brass parts. Our team makes sure you get parts that fit your needs.

Brass cnc machining is used in many industries. You find brass parts in:

Automotive: valves, bushings, gears, and connectors

Electronics: terminals, switches, and sockets

Plumbing: faucets, pipe fittings, and couplings

Marine: anti-corrosive pumps and valves

Architecture: decorative handles and luxury fixtures

Musical instruments: trumpet and saxophone parts

JOC Machinery makes hinges, knobs, bushings, nuts, bolts, and jewelry. Our cnc brass machining gives you accurate, strong, and nice-looking parts for any job.

If you want good brass machining, pick a skilled partner. JOC Machinery gives you steady quality and help for all your cnc machine brass needs.

Knowing about brass composition and grades helps you pick the right material. The table below shows how each brass type works for different jobs:

Brass Type | Properties | Applications |

|---|---|---|

Alpha Brass | Very easy to bend | Used for shaping |

Beta Brass | Stronger than other types | Used for tough jobs |

Tin Brass | Resists rust well | Good for marine parts |

Manganese Brass | Wears down slowly | Used for stressed parts |

Choosing the best brass grade gives you better machining. You get high accuracy and parts that last longer. You also save money and get steady results in brass cnc machining. For the best results, ask JOC Machinery experts. They use advanced cnc machines and strict checks to make sure your needs are met.

Brass contains copper and zinc. You may find small amounts of lead, tin, or nickel. The mix changes how brass looks and works. You choose the right composition for your project.

You get the best results with C360 Free-Cutting Brass. This grade offers easy machining, smooth surfaces, and strong parts. JOC Machinery recommends C360 for fast and accurate CNC machining.

Yes, you can use brass outdoors. Brass resists corrosion and lasts a long time. You often see brass in marine hardware, plumbing, and architectural fixtures.

You look at your part’s needs. If you want easy machining, pick C360. For bending or forming, choose C260. JOC Machinery helps you match brass grades to your application.

You contact JOC Machinery for advice. Our team guides you in choosing the best brass grade and machining process. You get quality parts and reliable support.

Tip: Reach out to JOC Machinery for custom brass solutions and expert guidance.

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com