Views: 0 Author: Site Editor Publish Time: 18-08-2025 Origin: Site

When you want the best bronze for machining, you pick from these grades: C932 (SAE 660), C954, C260, C510, 642, C630, and C863. These bronze types are good because they are easy to machine, strong, and last a long time. C932, C954, and C510 are used a lot in cnc machining for bearings, pumps, and electrical connectors. Each bronze grade has special features, so you can choose the right one for your job.

Here is a quick look at some popular bronze grades and their uses:

Grade | Machinability | Typical Uses |

|---|---|---|

C932 | High | Bearings, bushings |

C954 | Medium | Pumps, marine hardware |

C510 | Good | Springs, electrical connectors |

Pick the best bronze grade for your CNC project. Some common choices are C932, C954, and C510. Each one works well for different jobs.

Bronze is easy to machine and lasts a long time. It gives a smooth finish and does not wear out fast. This makes it good for parts that rub or get pushed.

Think about what your project needs. Look at things like how strong the bronze is. Check if it can fight rust and if it is easy to machine.

Use the right machining steps to get good results. Use cutting fluids to help. Watch your tools so they do not get worn out. Make sure chips are controlled for better work and parts.

Ask experts for help if you need it. JOC Machinery can help you pick the right bronze grade. They can also help you during your machining work.

Bronze is strong and easy to work with. It gives a smooth finish and does not wear down tools quickly. You can make detailed parts because bronze bends well. Aluminum is softer, so it is easier to cut. Brass cuts fast and makes tiny chips. Bronze is harder to machine than brass. But bronze parts last longer and work better.

Tip: For better accuracy and control, use bronze alloys with lead or tin. These help make machining easier and control chip size.

Bronze lasts a long time and works well under stress. It is good for parts that face friction and tough conditions. Tin bronze, phosphor bronze, and aluminum bronze are strong and resist wearing out. They also fight rust and damage from water. Bronze is great for bushings, gears, and marine parts. It has low friction, so moving parts last longer. Bronze does not rust easily, even in salty or acidic places.

Bronze Alloy | Properties |

|---|---|

Tin Bronze (SAE 660) | Wears out slowly, strong, and resists rust |

Phosphor Bronze | Very strong, does not rust in sea water |

Aluminum Bronze | Gets hard easily, fights rust very well |

Silicon Bronze | Resists rust in salt water and acid |

Copper-Nickel Bronze | Fights rust, strong, and tough in hot or cold |

Leaded Bronze | Easier to machine because lead helps cutting |

Beryllium Bronze | Very strong and carries electricity well |

Bronze machining is used in many fields. It makes parts for boats, machines, electrical items, and musical instruments. Bronze is chosen for propellers, bushings, bearings, connectors, and springs. It is also used for railings and fasteners because it looks nice and does not rust.

Application Category | Specific Uses |

|---|---|

Marine Applications | Propellers, fittings, valve parts |

Industrial Machinery | Bushings, bearings |

Electrical Components | Connectors, springs |

Architectural and Aesthetic | Railings, fasteners |

Musical Instruments | Cymbals, strings |

Bronze machining gives you strong, easy-to-work parts that last a long time. It is a good choice for many jobs.

When picking cnc machining bronze, you should know each grade is different. Each bronze type has special things that make it good for certain jobs. Let’s look at the best bronze grades for cnc machining.

C932, also called SAE 660, is a very popular bronze grade for cnc machining bronze parts. It is easy to machine and works well for many things. This bronze is strong, wears out slowly, and does not rust fast. It is great for moving parts that need to last.

Key Properties:

Property | Value |

|---|---|

Tensile Strength | 35 ksi |

Yield Strength | 20 ksi |

Elongation | 10% |

Density | 0.322 lb/in³ |

Modulus of Elasticity | 14,500 ksi |

Common Uses:

Bearings and bushings

Pumps and valve parts

Washers and fasteners

Machine tool bearings

Automotive fittings

C932 is a top pick for cnc machining bronze bushings, thrust washers, and pump parts. It works well for medium loads and speeds.

C954 aluminum bronze is strong and does not wear out fast. You can use this bronze for heavy-duty cnc machining bronze parts. It has aluminum, which makes it harder and helps stop rust.

Key Properties and Uses:

Bronze Alloy (UNS No.) | Common Name | Machinability Rating | Common Applications |

|---|---|---|---|

C95400 | Aluminum Bronze | 60 | Heavy-duty bearings, bushings, gears, valve parts, marine hardware |

People often use C954 for gears, bushings, and marine hardware. It is good in tough places where you need strong parts that last.

C260, called cartridge brass, is a copper-zinc alloy. It is not really a bronze, but people use it in cnc machining bronze jobs because it is easy to work with. This alloy is simple to shape and cut, so it is good for tricky parts.

Key Characteristics:

Characteristic | Description |

|---|---|

High Strength and Durability | Tensile strength from 380–550 MPa, good for automotive and hardware parts |

Excellent Workability | Easy to form into complex shapes, ideal for precision cnc machining bronze components |

Corrosion Resistance | Good in fresh and saltwater, used in plumbing and marine parts |

Electrical Conductivity | 28% IACS, good for electrical connectors |

Attractive Appearance | Golden-yellow color, easy to polish, used for decorative parts |

You can use C260 for ammo casings, musical instruments, plumbing, and electronic connectors. It can be pulled into thin wires or sheets.

C510 phosphor bronze is a tough and strong alloy. It is good for cnc machining bronze parts that must handle stress and wear. It has tin and phosphorus, which make it stronger and help stop rust.

Main Properties and Uses:

Property | Description |

|---|---|

Mechanical Properties | High tensile strength (up to 450 MPa), excellent fatigue resistance |

Corrosion Resistance | Improved resistance to corrosion |

Wear Resistance | Superior wear resistance, ideal for moving parts |

Electrical Conductivity | Good for electrical connectors |

Typical Applications | Automotive parts, electrical connectors, springs, gears |

You can use C510 for springs, bushings, gears, and connectors. It is a great choice for precision cnc machining bronze parts in electronics and machines.

642 bronze is a silicon-aluminum bronze. This alloy is strong and easy to machine. It does not rust and wears well, even in hard places. You can use it for valve stems, fasteners, and marine hardware.

High strength and toughness

Good machinability for cnc machining bronze parts

Excellent resistance to corrosion, especially in marine settings

Used for valve stems, bushings, and high-strength fasteners

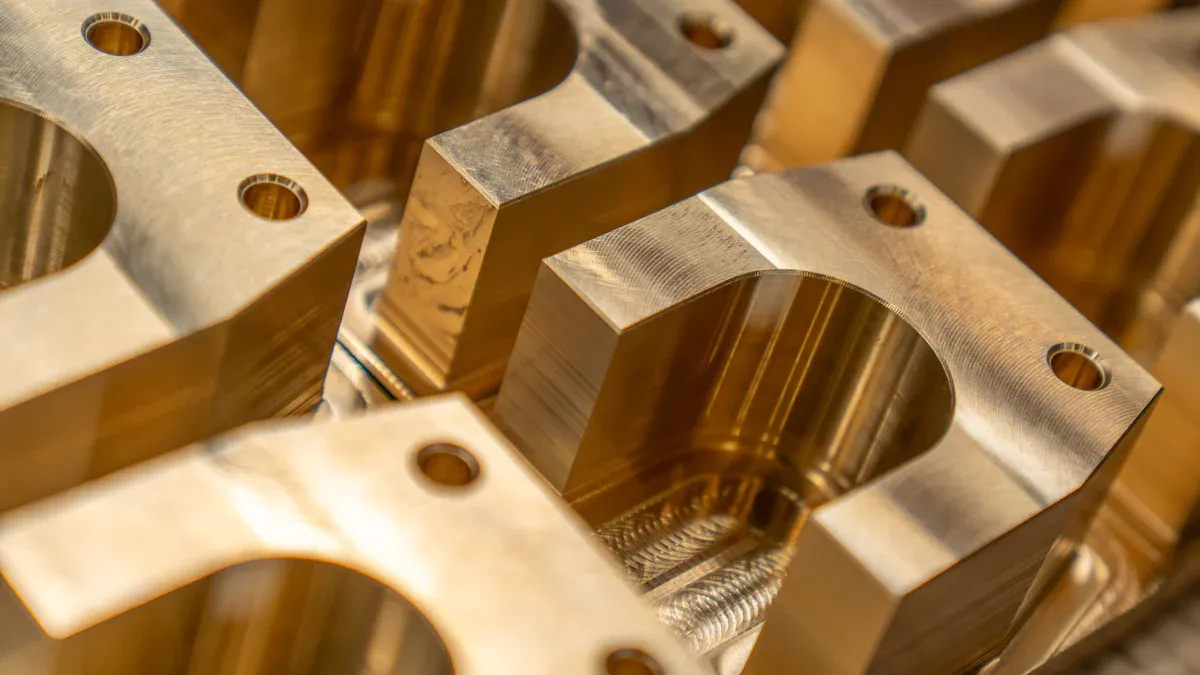

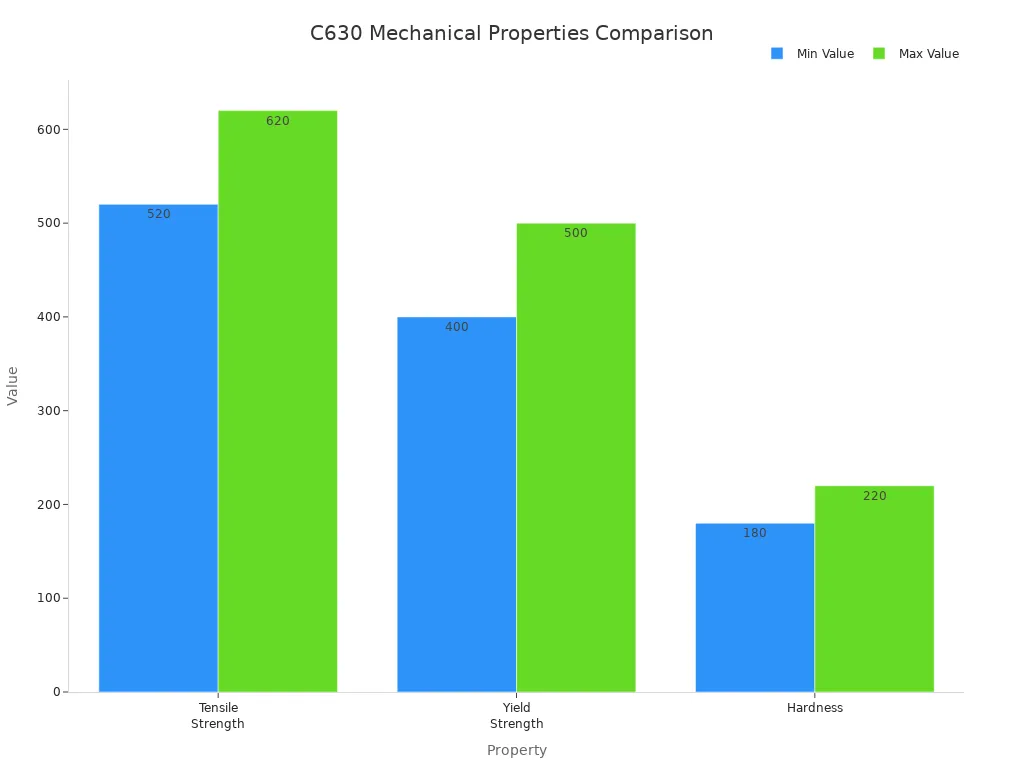

C630 nickel aluminum bronze is one of the strongest bronze alloys for cnc machining bronze. It has nickel, aluminum, and iron, which make it very strong and hard. You use this bronze when you need parts that can take heavy loads and lots of wear.

Mechanical Properties:

Property | Value (Typical) |

|---|---|

Tensile Strength | 520–620 MPa |

Yield Strength | 400–500 MPa |

Hardness | 180–220 HB |

You can use C630 for heavy-duty bearings, gears, and marine hardware. It is perfect for cnc machining bronze parts that face lots of rubbing and need to last.

C863 leaded tin bronze is a strong alloy with lead added. The lead makes it easier to machine, so you can make tricky cnc machining bronze parts. This bronze is good for heavy-duty jobs that move slowly.

Applications and Machinability:

Application Type | Description |

|---|---|

Valve/Hydraulic Parts | Used in valve and hydraulic components |

Load Bearings | Great for heavy-duty load-bearing applications |

Gear Castings | Used for gears and wear hardware |

Architectural Elements | Valued for long life in buildings |

Machinability rating of 80, so you can machine it easily

Used for bridge turntables, gears, and valve stems

Handles heavy loads at low speeds

Tip: If you need cnc machining bronze parts for tough and tricky shapes, C863 is a smart pick.

Picking the right bronze for cnc machining depends on what your project needs. Each bronze grade gives special benefits for different cnc machining bronze jobs. You can count on these grades to give you strong, long-lasting, and accurate parts for your next project.

When you pick bronze for cnc machining, you want to know how easy it is to shape. Machinability means how quickly you can cut, drill, or mill bronze without hurting your tools. Some bronze alloys have lead. Lead helps chips break off and makes machining smoother. You get better results and save time.

Here is a table that shows how different bronze grades compare in machinability. The scores use C360 Free Cutting Brass as a baseline of 100.

Bronze Grade | Relative Machinability (vs C360 Brass = 100) |

|---|---|

C54400 (Leaded) | 80 |

High Lead | 70-80+ |

Other Grades | 20-50 |

Tougher, Gummy | 20-60 |

Additional Grades | 30-60 |

If you want fast and easy bronze cnc machining, choose a leaded bronze like C54400. Tougher bronze grades need slower speeds and sharper tools. High-lead bronze gives smoother finishes.

Tip: Always check the machinability rating before you start cnc machining. This helps you plan your work and pick the right bronze.

Bronze is strong and does not wear out quickly. You want bronze parts that last and can handle stress. Some bronze grades are much stronger than others. Bronze 642 has high strength and hardness. Bronze 932 bends before breaking because it has good elongation.

Here is a table that compares two popular bronze grades:

Bronze Grade | Ultimate Strength | Yield Strength | Fatigue Strength | Shear Strength | Hardness (Brinell) | Elongation at Break |

|---|---|---|---|---|---|---|

Bronze 642 | 83 ksi | 42 ksi | 50 ksi | 56 ksi | 172 | 12% |

Bronze 932 | 40 ksi | 18 ksi | 16 ksi | 64-78 ksi | 65 | 20% |

Bronze 642 gives higher strength and better wear resistance. Bronze 932 is easier to machine and more flexible. Pick the bronze that fits your project’s needs for durability and performance.

Cost is important when you choose bronze for cnc machining. Some bronze grades cost more because they use rare metals or have special features. Leaded bronze usually costs less and is easy to find. High-strength bronze, like nickel aluminum bronze, costs more but lasts longer.

You can find bronze in many shapes and sizes. Most suppliers have common grades like C932 and C954. Special bronze grades may take longer to order. You save money by picking a bronze grade that matches your job and is easy to get.

Note: If you need help finding the right bronze for your cnc machining project, JOC Machinery offers many bronze alloys and expert support.

When you start a bronze machining job, you need to pick the right bronze alloy. Each alloy is good for different things. You should think about what your project needs most. Here are some things to look at:

Composition variation: Some bronze alloys have more tin, aluminum, or lead. These changes make the alloy stronger, easier to machine, or better at fighting rust.

Application needs: Think about if you need strong parts, parts that last, or parts that handle heat well.

Bronze part quality: If you want parts that last long, choose bronze alloys that are tough.

Softness and galling: Bronze is softer than steel. This can cause problems like galling, so you may need to change how you machine it.

If you need help, you can ask JOC Machinery. We know a lot about metal cnc machining and can help you pick the best bronze for your job.

Bronze machining needs tight tolerances for parts that fit together well. You want your bronze parts to meet strict standards. Some bronze alloys are easier to machine with close tolerances. C932 and C510 are good choices for jobs that need high precision. Always check how easy the alloy is to machine before you start. This helps you get the best quality bronze parts.

Tip: Use measuring tools to check your bronze parts while you work and after you finish. This helps you find mistakes early and keeps your project going well.

Budget is important when you machine bronze. Some bronze alloys cost more because they use rare metals or have special features. You should think about the cost and what you get from each alloy.

Aspect | Impact on Budget Constraints |

|---|---|

Material Choice | More expensive materials can make your project cost more. |

Machinability | Bronze is worth the price for tricky jobs. |

Cost-Effectiveness | Think about cost and material features to save money. |

Project Complexity | Simple parts cost more, but hard parts can be made faster. |

Bronze machining costs change if your parts are simple or complex. Simple parts may cost 30-40% more, but hard parts only cost 10-20% more. If the alloy is easy to machine, you save money by skipping extra steps and getting a smooth finish. How easy it is to find the material and how long machining takes also change the total cost.

You can get better results with these tips:

Employ cutting fluid: Use water-based coolant or synthetic oil to lower friction and stop chips from building up.

Check tool wear: Bronze can wear out tools faster than softer metals. Look at your cutting edges often.

Check the finish: Use measuring tools to make sure your bronze parts look right.

Control chips: Long chips can wrap around tools. Use chip breakers and change your cutting speed.

Avoid thin wall distortion: For thin bronze parts, use air cooling and take shallow cuts.

If you need custom bronze parts, JOC Machinery can help. We make bearings and gears and help with all kinds of bronze machining. Our team checks every part for quality and accuracy.

Many customers trust us for their bronze machining jobs. We care about bronze part quality and always give good results.

When picking a bronze grade for CNC machining, think about what your project needs. Match the bronze’s features to the job, like if it needs to carry electricity, fight rust, or handle tough places. Also, think about the design and how well the bronze will work.

Pick the bronze alloy that fits your job best.

Use good cutting tools and keep chips under control for better parts.

Plan your part design so it is easy to finish after machining.

Bronze Grade | Properties | Machinability | Applications |

|---|---|---|---|

642 Bronze | Strong, bends well, fights rust | Easiest to machine | Used in many fields |

PB1 Phosphor Bronze | Tough, machines well | Easy to machine | Used for many things |

If you need help, JOC Machinery can help you pick the right bronze for your CNC machining job.

Bronze makes strong parts that last a long time. It does not wear out or rust easily. You can shape bronze into small, detailed pieces. Many companies use bronze for bushings, gears, and valves. Bronze works well even in hard places.

C932 is the easiest bronze grade to machine. You can cut, drill, and shape it with less tool damage. This grade gives smooth surfaces and accurate shapes. Machinists often pick C932 for bushings and bearings.

Use sharp tools and the right cutting fluids. Try to control how chips break off while you work. Check the size of your part often. These steps help you get better surfaces and make your tools last longer.

Yes, bronze works for high-precision jobs. Grades like C510 and C932 help you keep tight measurements. You get parts that fit well and look the same every time. Always measure your parts during machining to make sure they are correct.

You can ask JOC Machinery for help. Their team helps you pick the best bronze grade and machining method. They give advice and check your bronze parts for quality.

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com