Views: 0 Author: Site Editor Publish Time: 15-08-2025 Origin: Site

It can be made to fit exactly right.

It needs no care because it lubricates itself, so machines stop less.

It works well for a long time and saves money.

JOC Machinery has many years of CNC machining bronze and investment casting experience. If you use the right methods, you can get accurate and steady results every time.

Bronze is tough and lasts a long time. This makes it great for CNC machining jobs that need accuracy.

Pick the best bronze alloy for your project. This helps your parts work well and last longer.

Use carbide tools when you machine bronze. This gives a smooth finish and helps tools last longer.

Use good cooling methods while machining. This stops things from getting too hot and keeps tools working well.

Take care of your CNC machines often. This helps them make bronze parts right and fast.

Bronze is a special material for CNC machining. It has many good features that help you get great results.

Bronze parts last a long time because they do not wear out fast.

Bronze slides easily against other surfaces because it has low friction.

Bronze does not rust or get damaged by water or air.

You can cut and shape bronze easily and make it very exact.

Bronze is strong and can hold heavy things.

Bronze can make its own oil, so you do not need to add much.

Bronze can move heat away during machining.

Bronze often works better than other metals in these ways. Brass is a little easier to machine, but bronze is stronger and does not rust as much. That is why bronze is a good pick for many projects that need exact parts.

JOC Machinery has used bronze and its alloys for a long time. The team knows how to get the best from bronze with CNC machining and investment casting. They help you pick the right bronze and make sure every part is made well.

Bronze is used in many jobs. You will see bronze parts where things need to be strong and last a long time. Here are some ways people use CNC machined bronze:

Application Type | Industries Involved |

|---|---|

Nuts and bolts | Agriculture, Automotive |

Threaded components | Heavy Vehicles |

Electrical terminals | Various Industries |

Taps | Various Industries |

Gears and bearings | Various Industries |

Bushings | Various Industries |

Screws | Various Industries |

Bronze is also found in bearings, marine pumps, and some machine parts. Bronze’s special features make it a good choice for these uses. When you work with JOC Machinery, you get their knowledge and their promise to do good work.

When you pick bronze for CNC machining, you have many choices. Each alloy is different and works best for certain jobs. Here are some common bronze alloys you might use:

C932 Bearing Bronze: This alloy is simple to machine. It has lead, which helps tools last longer and makes a smooth surface.

C954 Aluminum Bronze: This alloy is very strong and does not rust easily. It is good for hard jobs.

C544 Phosphor Bronze: This alloy bends well and carries electricity. It is also easy to machine.

You can find these alloys in many small parts and casting products at JOC Machinery. We have lots of bronze alloys for your needs.

You should look at bronze alloys before you start your work. The best alloy depends on what you need your part to do. Here is a table to show the differences:

Factor | Description |

|---|---|

Corrosion Resistance | Aluminum bronze and silicon bronze are best for wet or chemical places. |

Wear Resistance | Bearing bronze (C932) is good for moving parts because it stops friction. |

Machinability | Bearing bronze and phosphor bronze are easy to cut and help tools last. |

Strength and Elasticity | Phosphor bronze is strong and bends well, so it works for tough jobs. |

Aesthetic | Silicon bronze looks nice and is used for design. |

Environment | Always think about where the part will go, like in salty water or near chemicals. |

Complexity | Some bronze alloys are better for tricky shapes and close fits. |

You should always pick the bronze alloy that fits your project. Think about where it will be used, how much it will move, and how hard the shape is. If you need help, JOC Machinery can help you choose. We know a lot about bronze alloys and CNC machining. Our team can help you find the best alloy for your parts or casting.

Tip: Try a small piece of the bronze alloy before making a lot. This helps you find problems early and get the best results.

You need to set the right machining parameters to get the best results from cnc machining bronze. Bronze has good machinability, but each alloy responds differently to speed and feed rates. If you use the wrong settings, you can damage your tools or get a rough finish.

For 954 bronze, use a cutting speed between 700 and 1000 surface feet per minute (SFM) with a 0.5-inch cutter.

For aluminum bronze, set the cutting speed at 200 to 225 SFM.

If you use a four-flute cutter at 1000 SFM with a 0.003-inch feed per tooth, you will reach about 7640 RPM and 91 inches per minute (IPM).

Tip: Always check the manufacturer's recommendations for your specific bronze alloy before you start cnc machining bronze. This helps you avoid mistakes and keeps your process smooth.

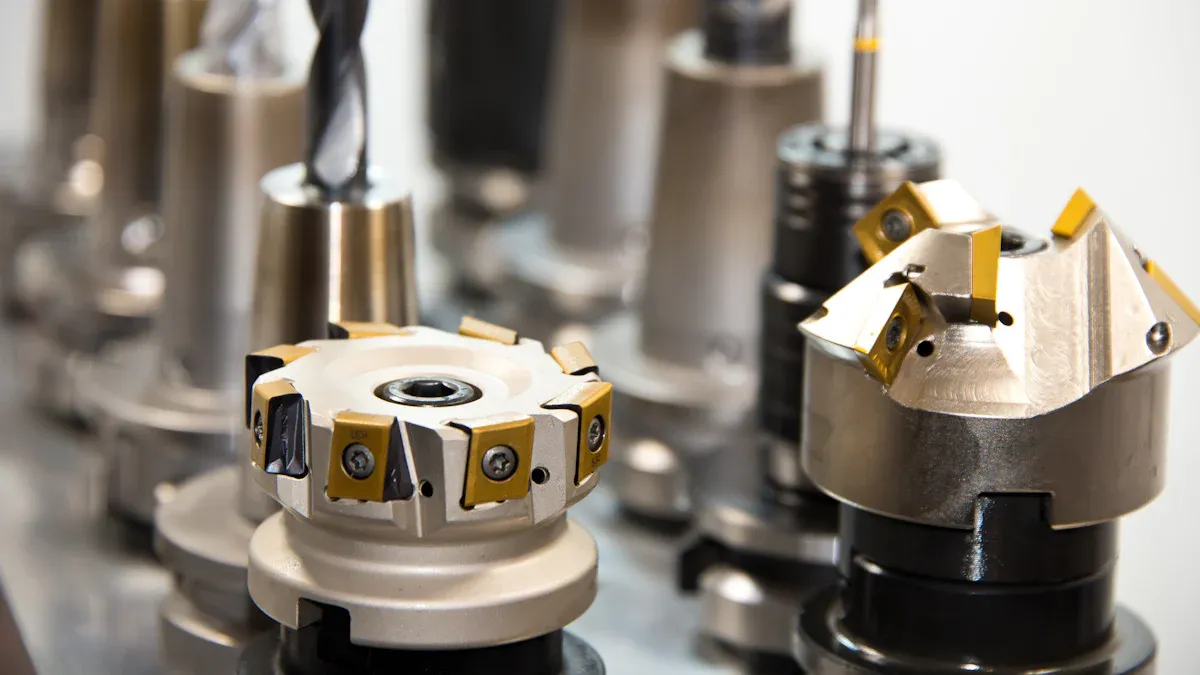

Choosing the right tool is key for bronze cnc machining. Bronze is tough, so you need tools that last and give a clean finish.

Carbide tools work best for bronze machining. They last longer and resist wear, which means you spend less time changing tools.

Optimized cutting tools help you get a smoother surface. They also reduce the roughness of your finished part.

Use tools with chip breakers. These help control the chips that come off during machining and keep your workspace safe.

The right tool design lowers cutting forces. This stops bronze from sticking to the tool and gives you a cleaner finish.

You can also use aluminum tools for some bronze alloys. These tools work well because they handle the heat and pressure of cnc machining bronze.

Bronze machining creates heat. If you do not control the temperature, you can damage both the part and the tool. You need to use the right cooling methods to keep everything running well.

Always use coolants and lubricants. These stop the bronze from overheating and protect your tools.

Oil-based coolants work well for bronze cnc machining. They cool and lubricate at the same time.

Additives in coolants help reduce rust, foam, and friction. This keeps your tools in good shape.

Apply coolant evenly with flood or mist cooling. This spreads the heat and keeps the bronze at a safe temperature.

Match the coolant type to your machining task and tool. This gives you the best results.

Try intermittent cutting if you see too much heat. This lets the bronze cool down between cuts.

Note: Good cooling not only protects your tools but also improves the surface finish of your bronze parts.

After you finish cnc machining bronze, you need to take extra steps to get the best surface quality. Bronze parts often need a smooth finish for their final use.

Deburr all edges to remove sharp spots and loose material.

Use fine-grit sandpaper or polishing wheels to get a shiny, smooth surface.

Clean the part with a soft cloth to remove any leftover dust or coolant.

Inspect the part for any marks or scratches. If you find any, repeat the polishing step.

For parts that need extra shine, use a buffing compound made for bronze.

A good finish makes your bronze parts look better and last longer. It also helps them fit and move well in machines.

Remember: JOC Machinery uses strict quality checks at every step of bronze cnc machining. This ensures you get parts that meet your needs every time.

When you machine bronze, you may face special problems. Knowing these problems helps you avoid mistakes. It also helps you keep your work smooth. Here are some common problems and ways to fix them.

Tool wear happens a lot when you machine bronze. Bronze is rough and can hurt your tools fast. You might see different tool damage like flank wear, crater wear, or built-up edge. Each kind of wear changes your tool and the finished part.

Flank wear gets worse if you use the wrong speed or coating.

Crater wear shows up if you pick the wrong tool or coolant.

Built-up edge happens when bronze sticks to the tool. This makes the surface rough.

Thermal cracking can happen if the temperature changes too much.

You can make tool wear less by:

Using carbide or PCD tools for longer use.

Lowering cutting speeds to keep things cool.

Using the right coolant to stop heat damage.

Picking tools with anti-stick coatings.

Switching from high-speed steel to carbide inserts helps tools last longer. It also makes production faster. Always check your tools for damage and change them when needed.

Machining bronze makes different chips. Sometimes you get segmented chips. These chips break easily and are simple to clean up. Other times, you get long chips. These are harder to remove and can hurt your tools.

To control chips:

Use chip breakers on your tools.

Change feed rates and cutting speeds.

Keep your workspace clean so chips do not pile up.

Good chip control keeps your work safe. It also helps you get a smoother finish on bronze parts.

Vibration can cause trouble when you machine bronze. It can make the surface look bad or even break your tools. Vibration happens if the part is not held tight or if the tool sticks out too far.

To lower vibration:

Use strong fixtures and clamps.

Keep tool overhang short.

Use sharp tools and climb milling.

Use flood coolant to keep things cool.

JOC Machinery uses strict quality checks to help you avoid these problems. Our factories have ISO9001 and TS16949 certifications. This means you get good and steady bronze machining every time.

Certification | Description |

|---|---|

ISO9001 | Quality management systems standard |

TS16949 | Quality management standard for automotive production |

Tip: Check your setup often and use the right methods. This helps you fix most bronze machining problems before they hurt your parts.

You want your bronze parts to look nice and work well. A good finish helps them last longer and fit better. There are different ways to finish bronze:

As-machined finish keeps the look from the cnc process. This is good for many parts.

Polishing uses smooth sand to make bronze shiny and smooth.

Brushing gives bronze a soft look with thin lines.

Grain blasting hides marks and makes the surface dull.

Grinding helps you get very close fits and a smooth finish.

JOC Machinery uses modern cnc machines in Jiangyin to make sure your parts look great. The team checks every part to see if it meets your needs.

You can get better results by changing how you machine bronze. Each type of bronze needs its own settings. Here is a table to help you:

Process Adjustment | Description |

|---|---|

Tool Maintenance | Check and sharpen your tools often. |

Workpiece Fixturing | Hold the bronze part tight so it does not move. |

Machining Parameters | Set the right speed, feed, and depth for each bronze alloy. |

Chip Control | Use chip breakers or special tool shapes to handle chips. |

Surface Finishing | Pick the best finish for how you will use the part. |

Watch the temperature in your cnc shop. Too much heat can cause mistakes and hurt your machines. Keep your shop cool and dry for the best results.

Taking care of your cnc machines helps your bronze parts stay accurate. It also keeps your shop working well. Do these things:

Check your cnc machines often to find problems early.

Oil moving parts to stop them from wearing out.

Clean your machines so dust and chips do not build up.

Get professional service to keep everything working right.

JOC Machinery’s factories have ISO9001 and TS16949 certifications. We follow strict plans to care for our machines at all our factories. This helps us make good cnc bronze parts every time.

If you want cnc machining you can trust for bronze, talk to JOC Machinery. Our team has lots of experience and happy customers. We can help you with your next project!

You can achieve great results in CNC machining bronze by following a few key steps. Focus on the right tolerances, critical features, and process settings. Always check your tools and avoid programming mistakes. Here is a simple checklist to help you:

Remove oils and dust before machining.

Inspect parts for any dirt or damage.

Use the correct cleaning and drying methods.

Make sure you know how to use all equipment.

If you have questions or need support, reach out to JOC Machinery. We are ready to help you succeed.

Bronze contains copper mixed with tin or other metals. You get better strength and wear resistance with bronze. Copper alone is softer and less durable. Bronze parts last longer in machines.

You should not use the same settings. Pure copper is softer and can gum up tools. You need slower speeds and sharper tools for copper. Bronze alloys handle higher speeds and give smoother finishes.

Copper is the main ingredient in bronze. You get improved conductivity and corrosion resistance from copper. Adding tin or aluminum to copper creates bronze alloys that work better for CNC machining.

You look at the job’s needs. Copper works well for electrical parts. Bronze is better for gears, bushings, and parts that need strength. You get more durability from bronze in moving parts.

Yes, copper gives bronze its reddish-brown color. The more copper in the alloy, the richer the color. You see different shades based on how much copper and other metals are present.

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com