Views: 0 Author: Site Editor Publish Time: 23-01-2026 Origin: Site

Think about all costs, not just the first price. Add in materials, tooling, and how fast they deliver to get real quotes.

Quality and doing the same thing every time are very important. Pick suppliers who check their work well to get steady results.

Check if the supplier knows your materials. Smart suppliers can make better parts that last longer.

Find suppliers who give good customer service. They should talk clearly and help you during your project.

Plan for working together for a long time. A good supplier can help you do better and save money later.

When you compare investment casting services, look at more than just the first price. The total cost has many parts. It includes materials, tooling, how many pieces you need, finishing, and how fast you get your order. If you gather all your project details before asking for prices, you get better quotes. This helps you avoid surprises later.

Material and tooling costs are a big part of your budget. The alloy you pick can change the price a lot. Carbon steel is much cheaper than titanium or nickel alloys. Here is a table that shows usual costs for different materials:

Cost Component | Typical Cost Range (USD) |

|---|---|

Carbon Steel | $1.50 – $2.50 per lb |

Stainless Steel | $2.50 – $4.50 per lb |

Aluminum Alloy | $2.00 – $3.50 per lb |

Nickel Alloy | $15.00 – $40.00 per lb |

Cobalt Alloy | $25.00 – $60.00 per lb |

Titanium | $20.00 – $50.00 per lb |

Material prices can change because of market trends or supply chain problems. Some investment casting supplier companies may add extra charges if prices go up. Tooling costs depend on how hard your part is to make.

How many parts you order changes the price for each one. If you order more, each part costs less. This is because fixed costs, like tooling, spread out over more pieces. Here is a simple table:

Production Yield | Cost per Unit Weight |

|---|---|

Low | High |

High | Low |

Tip: If you need lots of parts, you can save money by ordering more at once.

Finishing steps, like sandblasting or polishing, add to the cost but make your part better. A smooth finish helps your part last longer and look nicer. Some finishes help lower friction or stop rust. Here are some common finishing choices:

Sandblasting: Takes away flaws and gets surfaces ready.

Shot Peening: Makes parts stronger, good for cars and planes.

Grinding and Polishing: Makes parts shiny and very exact.

You should think about how perfect you want your finish and how much you want to spend.

Getting parts faster usually costs more. If you need parts quickly, investment casting services may charge extra fees. Planning ahead helps you avoid these charges and keeps your project moving. Good customer service can help you know how long things will take and what to expect.

If you look at all these things, you understand the real cost better. Always ask for clear quotes and check if advanced quality control is included. This helps you make smart choices for your project.

You want your parts to fit the right size every time. Good investment casting services check each part with special tools. You should pick suppliers who have strong quality checks and do well on the first try. Here is a table that shows important ways to measure quality:

KPI | Definition | Advantages | Disadvantages | Industry Benchmarks |

|---|---|---|---|---|

First-Pass Yield Rate (FPR) | Measures how many good parts are made out of all parts. | Makes less waste, saves money, and helps finish faster. | Might hide bigger problems, does not count parts that fail later. | Try for more than 95% for very exact casting. |

Customer Concentration Risk | Checks if most money comes from just a few customers. | Shows if business is steady, helps plan, and shows risk. | Can be bad for big deals, may not see small customer risks. | Keep under 30% for steady business. |

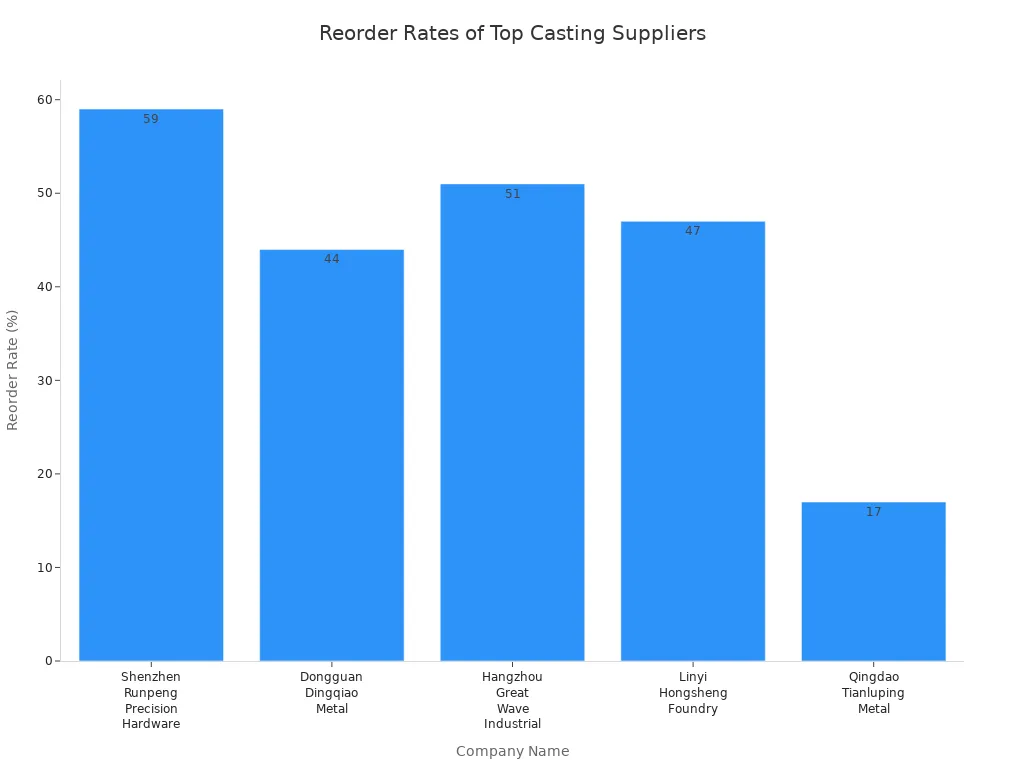

Repeatability is important for your project. Suppliers with high reorder rates show they do a good job again and again. Here is how some top suppliers compare:

Company Name | Reorder Rate |

|---|---|

Shenzhen Runpeng Precision Hardware Co., Ltd. | 59% |

Dongguan Dingqiao Metal Co., Ltd. | 44% |

Hangzhou Great Wave Industrial Technology Ltd | 51% |

Linyi Hongsheng Foundry Co., Ltd. | 47% |

Qingdao Tianluping Metal Products Co., Ltd. | 17% |

Strong design teams help suppliers make better parts. You get parts that fit better and have fewer mistakes. Suppliers with their own engineers can:

Make better parts with special tools.

Meet tight size rules for safety and use.

Save time by needing less extra work.

New machines help suppliers make parts faster and with fewer mistakes. Top investment casting supplier companies use special ovens, robots, and computer programs. Here is a table that shows some common tools:

Supplier | Equipment/Technology Description |

|---|---|

ABP Induction Systems | New technology for better work and results. |

Foseco | Products for treating metals of many kinds. |

Remet | Good help and choices for binding. |

Shell-O-Matic | Robots for making shells and parts. |

PCC Airfoils | Special ovens for hard-to-make parts. |

Inductotherm Group | Advanced ovens for steady, high-quality parts. |

General Innovations | Computer programs and robots for fast, exact work. |

Tip: Robots and digital tools like 3D printing and computer programs help suppliers make tricky parts fast and better.

You should see if suppliers know how to work with your materials. Common alloys are stainless steel, aluminum, brass, nickel-based, and cobalt-based alloys. Suppliers with experience know how to use these materials and the right ways to cast them. This means your parts will last longer and work better.

Financial stability means your supplier can help you for a long time. You should check gross margin percentage and customer concentration risk. Good suppliers have a gross margin over 80% and keep customer concentration risk under 30%. This helps you avoid late deliveries and poor service.

Start by getting quotes from each investment casting manufacturer. A clear Request for Quote, or RFQ, helps you get the right prices. This also stops confusion later. Here are some steps to help you:

Write an RFQ that tells what you need for casting.

Say how many parts you want and what metal you need.

Add the size, quality rules, how to check, and finish you want.

Ask for a list of costs for tooling, machining, and finishing.

Use a checklist to compare things like price, quality, delivery, and shipping.

Tip: Always check that every quote has the same details. This makes it easy and fair to compare.

You might see that quotes look different from each supplier. Some show every cost, but others put costs together. Here is a table to help you know what to look for in a quote:

Element | Description |

|---|---|

Unit cost | The price for each part. |

Tooling/mold fee | The cost to make the molds for your parts. |

Lead time | How long it takes to make and deliver your order. |

Shipping method and cost | How your parts will be shipped and what it will cost. |

Payment terms | When and how you need to pay. |

After-sales service | Help you get after your purchase, like fixing defects or handling returns. |

You want a supplier who can do the whole job well. Look at their experience, quality, and extra help. Here is a simple way to check what they can do:

See if the supplier has worked in your field before.

Make sure they have the right quality papers.

Ask if they can do the needed machining to stop problems.

You can also use this table to compare important things:

Criteria | Description |

|---|---|

Design Optimization | In-house engineers who improve designs and tooling for better quality and lower cost. |

Systems that check parts and make sure they meet your needs at every step. | |

A team that answers your questions and helps you finish your project on time. | |

Experience | Years of work in your industry, which helps them solve problems quickly. |

Proof that they meet industry standards for quality. | |

Value-Added Services | Extra help like advice on metals or design changes to make your parts better. |

Top suppliers also show their skills in these areas:

Critical Area | Description |

|---|---|

Mold Maintenance | They keep logs and schedules to track mold use and repairs. |

Process Simulation | They use computer models to find and fix problems before making your parts. |

Inspection Technology | They use advanced tools like X-ray machines and CMMs to check quality. |

Material Traceability | They provide certificates that show exactly what materials they used for each batch. |

Statistical Process Control | They use charts to prove they can make parts the same way every time. |

Note: Suppliers with strong technical skills can find problems early and keep your project safe.

Always check what other customers say about a supplier. Ask for names and look at their old projects. This helps you see if they finish on time and make good parts. Many companies use new tools like 3D CAD and special software to make better designs and fewer mistakes. This means you get better samples and less waiting.

When you check a supplier, look for these things:

Customer feedback and stories that show how the supplier fixed real problems.

Good reviews about delivery and product quality.

Examples of projects like yours.

You can also use this table to help you review:

Criteria | Description |

|---|---|

ISO Certification | Check if the foundry has ISO9001 certification. |

Production Quality Monitoring | See how they track quality during pilot and full production. |

Heat Treatment Specification | Review how they heat and cool parts to meet your needs. |

Defect Analysis | Ask how they find and fix casting defects. |

QA/QC Control | Look at their quality assurance and control steps. |

Material Certificate | Request original certificates to confirm the right materials were used. |

Inspectors should know the rules for checking castings.

Ask about any parts that failed and why they failed.

Check if the supplier uses data to find and fix defects.

A good investment casting service uses strong quality systems. Most suppliers follow ISO rules, which means they check quality at every step. Here is a table that shows what to look for:

Quality Management System | Description |

|---|---|

ISO Standards | Suppliers use ISO-based systems to control quality from start to finish. |

Quality Control Measures | Every step includes checks and records, with staff doing random and final inspections. |

Documentation | Orders come with flow charts and records, sometimes kept for decades. |

Suppliers with ISO 9001 papers show they care about quality, safety, and the environment. This means:

They work better and keep getting better.

They meet customer needs and keep you happy.

They manage risks and stop problems.

They follow rules and pass outside checks.

Tip: Always ask for proof of certification and check if the supplier keeps good records. This helps you trust their work and results.

By following these steps, you can compare suppliers fairly and pick the best one for your project.

You need to look at both cost and performance before you choose a supplier. Low prices may seem good, but poor quality can hurt your results. High performance means you get strong, reliable parts. You can use a simple table to compare what matters most:

Factor | Why It Matters | What to Check |

|---|---|---|

Price | Stays within your budget | All costs included |

Quality | Parts work as needed | Certifications, reviews |

Delivery Speed | Keeps you on schedule | Lead times, guarantees |

Tip: Always ask yourself if the lowest price gives you the best value for your needs.

You should think about the total value, not just the price tag. Good suppliers help you save money over time. They offer fewer defects, better support, and faster fixes. You can measure return on investment (ROI) by looking at these points:

Fewer mistakes mean less waste.

Fast help keeps your project moving.

Strong parts last longer and need fewer repairs.

ROI helps you see which supplier gives you the most for your money. You can use a checklist to compare suppliers:

Does the supplier offer support after delivery?

Are repairs and replacements easy to get?

Will the parts help your project succeed for a long time?

You want a supplier who will help you now and in the future. Long-term partnerships build trust and make your work easier. Suppliers who care about your needs will listen and solve problems quickly. You can look for these signs:

The supplier answers questions and gives updates.

They offer advice to improve your parts.

They keep promises and deliver on time.

Building a strong partnership helps you avoid problems and reach your goals faster.

Picking the right investment casting service is about cost and performance. You follow easy steps to compare suppliers. This helps you make good choices. You think about what your project needs now. You also think about working with suppliers in the future.

Check each supplier using your list.

Look at quality, price, and help.

Trust helps you do well for a long time.

Tip: Be sure when you decide. Comparing carefully helps you get the best results for your project.

Investment casting uses a wax pattern to make a mold. You pour metal into the mold to create a part. You get parts with smooth surfaces and detailed shapes.

You look at strength, cost, and how the part will be used. You ask your supplier for advice. You compare common alloys in a table.

Material | Strength | Cost |

|---|---|---|

Stainless | High | Medium |

Aluminum | Medium | Low |

Titanium | Very High | High |

You give all details so suppliers can give accurate prices. You avoid hidden costs. You help them plan for your needs.

Tip: Always share drawings, material choice, and order size.

You ask for ISO certificates. You review their inspection steps. You look for customer reviews about quality.

Request proof of certification

Ask about their inspection process

Read feedback from other buyers

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com