Views: 0 Author: Site Editor Publish Time: 06-08-2025 Origin: Site

When comparing galvanized steel vs stainless steel, there are significant differences in strength, durability, and cost. Stainless steel offers greater strength and superior resistance to rust, making it ideal for demanding environments and long-lasting applications. On the other hand, galvanized steel is more budget-friendly, making it suitable for land-based projects or when cost savings are a priority. Stainless steel is commonly used in coastal areas and food processing facilities, while galvanized steel is often chosen for fences and construction work. Whether you are a homeowner, hobbyist, or professional, understanding these distinctions is important when selecting materials for metal casting or steel forging projects.

Stainless steel is stronger than galvanized steel. It also resists rust better. This makes it good for hard jobs and tough places.Galvanized steel costs less at first. It works well for projects in easy conditions. You do not need high strength for these jobs.Stainless steel lasts longer and needs little care. It is best near the sea or with chemicals. This can save money over time.Galvanized steel needs checks and repairs often. It is good for outdoor things like fences and roofs. It is a good choice if you have a small budget.Pick your steel type based on what your project needs. Think about strength, where you use it, and your budget. This helps you get the best value and results.

Galvanized steel is regular steel with a zinc layer on top. The zinc helps stop rust but does not make the steel stronger. In building projects, galvanized steel’s tensile strength is between 380 and 550 MPa. Its yield strength is from 220 to 500 MPa. These numbers depend on the base steel grade, like S275 or S355. The zinc makes the surface harder and helps stop scratches. But it does not make the steel itself stronger. The steel’s chemical makeup, like how much silicon or phosphorus it has, can change the zinc layer’s thickness and quality. Still, the main job of the zinc is to stop rust, not to make the steel stronger.

Tip: Galvanized steel is a good choice if you need something strong but also want to save money.

Stainless steel is different because it is an alloy. It has iron mixed with chromium, nickel, and sometimes molybdenum or carbon. These parts help stainless steel fight rust and make it stronger than galvanized steel. Grades like 304 and 316 can have tensile strengths up to 850 MPa. The alloying elements are in the whole metal, not just on the outside. So, stainless steel stays strong even if you cut or bend it. It is also tough and can handle heavy loads and high pressure. This makes it great for hard jobs.

Property/Aspect | Stainless Steel | Galvanized Steel |

|---|---|---|

Tensile Strength (MPa) | Up to 850 | 380–550 |

Yield Strength (MPa) | 210–600 | 220–500 |

Main Composition | Iron, Chromium, Nickel | Iron, Zinc coating |

Stainless steel is usually stronger than galvanized steel. Tests show stainless steel can have much higher tensile strength. The chromium and nickel in stainless steel help make it strong and tough. Galvanized steel is good for jobs where you do not need the highest strength and want to save money. But if you need something very strong, like for metal casting or steel forging, stainless steel is better. Always think about what your project needs before you choose.

Galvanized steel has a zinc layer that protects it from rust. The zinc acts like a shield and keeps the steel safe. This layer wears away first before the steel gets damaged. In many outdoor places, galvanized steel can last 45 to over 100 years. How long it lasts depends on where you use it. In the countryside, it can last more than 80 years. But near the ocean or in factories, it may need fixing after 10 to 20 years.

Things like wet air, salty wind, acid rain, and pollution can make the zinc break down faster. Cleaning and checking for scratches helps stop rust and keeps it strong. Galvanized steel is a good choice for metal casting or steel forging if the weather is not too harsh. It saves money in these places.

Stainless steel is very good at fighting rust and lasts a long time. It has chromium, which makes a thin, invisible layer on the outside. This layer stops rust and keeps the steel safe, even if it gets scratched. If the surface is damaged, air helps fix the layer fast. This means stainless steel can last 50 to 100 years or more, even in tough places like near the sea or in chemical plants.

Stainless steel is used where rust is a big problem. It does not need much care, so you save time and money. Some types, like 316 stainless steel, are even better for harsh places.

If you want steel that fights rust the best and lasts longest, pick stainless steel. It stays strong for many years, even in salty or dirty air. Galvanized steel is good for places that are not too rough and costs less at first. But it might need more care and will not last as long in hard conditions.

Feature | Galvanized Steel | Stainless Steel |

|---|---|---|

Corrosion Resistance | Good (zinc coating) | Excellent (chromium oxide layer) |

Lifespan | 10–100+ years (depends on environment) | 50–100+ years (even in harsh settings) |

Maintenance | Regular cleaning and inspections needed | Minimal, thanks to self-healing surface |

Rust Protection | Zinc layer slows rust | Chromium layer prevents rust |

Tip: If your project is near the sea, in a factory, or around chemicals, stainless steel is the best for long-lasting strength and rust protection.

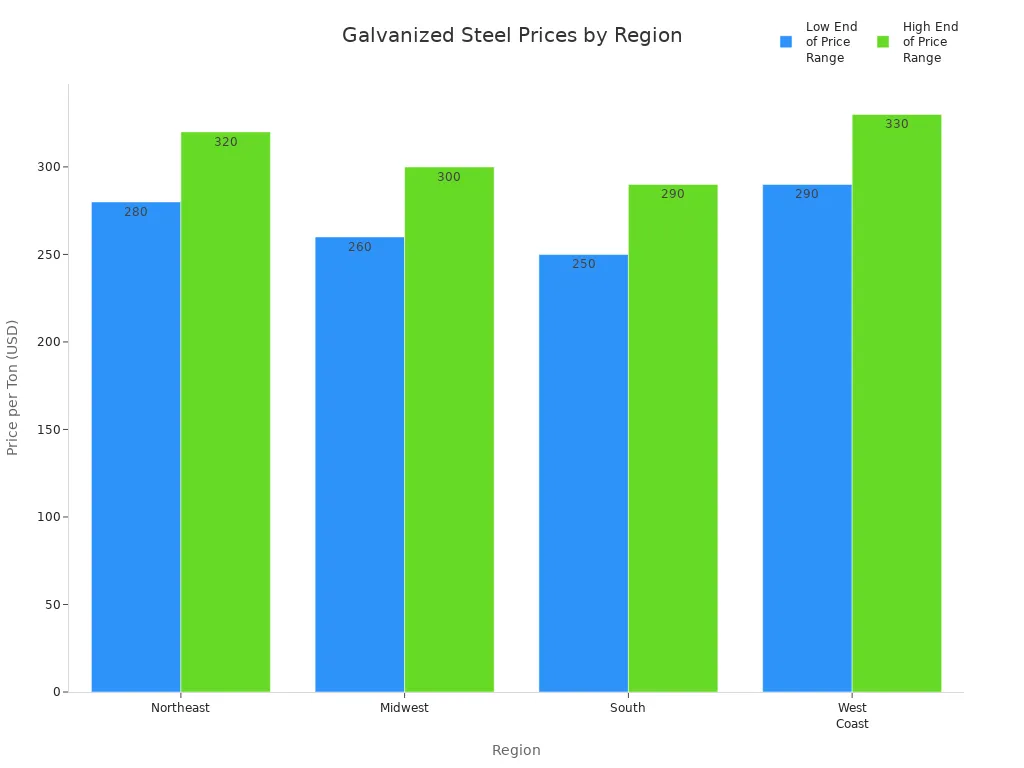

When you look at the starting price, there is a big gap. Galvanized steel is cheaper because it only needs a simple zinc coating. This makes it cost less to make. The table below shows how much each type costs:

Grade | Price Range (per pound) | Typical Use |

|---|---|---|

Clean | $0.35 - $0.45 | Sheet metal |

Mixed | $0.25 - $0.35 | Construction scrap |

Dirty | $0.15 - $0.25 | Contaminated pieces |

304 stainless steel costs about $0.30 for each pound. 316 stainless steel can cost up to $0.45 for each pound. These prices are higher because the alloys are expensive and making it is harder. If you need a lot of steel, these price differences can add up fast.

You also need to think about costs over time. Galvanized steel needs to be checked often and sometimes fixed. This is important if the zinc layer gets scratched or damaged. Over 20 years, you might spend more on fixing and replacing it. Stainless steel does not rust easily and is much tougher. It does not need much care and rarely needs to be replaced, even in hard places like near the sea or in factories.

Aspect | Galvanized Steel | Stainless Steel |

|---|---|---|

Initial Cost | Lower upfront cost | Higher upfront cost |

Maintenance | Occasional repairs, inspections | Minimal maintenance needed |

Lifespan | 25–50 years, more in mild settings | Up to 80 years, even in harsh environments |

Total Cost Over 20 Years | Cost-effective for moderate use | More cost-effective in harsh conditions |

If you want to spend less at first, galvanized steel is a good pick for many building jobs. It works well for fences, roofs, and other basic needs. Stainless steel costs more at the start, but you save money later if your project faces bad weather or chemicals. You will not need to fix or replace it as much. For big jobs like bridges or power towers, galvanized steel gives you a good mix of strength and price. For food, marine, or chemical work, stainless steel is worth the extra money over time.

Tip: Always choose the right material for your project and where it will be used. JOC Machinery Co., Ltd. has both types, so you can pick what fits your budget and needs best.

Pick galvanized steel if you want something strong but not too expensive. It works well outside or in places that are not too harsh. This means it is good for towns or farms, but not near the ocean or where there are lots of chemicals. The zinc coating helps stop rust, so it is smart for things like fences, barns, roofs, and utility poles. Many builders use it for bridges, tunnels, and highways because it is strong and costs less.

If you do not have a lot of money to spend, galvanized steel is a good choice. You can find it in car parts, farm tools, and building jobs where you only need some rust protection. For things like handrails, ducts, or beams, it is easy to cut and weld. It also looks plain, which is fine for places where looks do not matter much.

Tip: Galvanized steel is great if you need to save money and your project is not in a very wet or dirty place. You will not need to fix it much in mild weather, but check it more often if there is a lot of water or pollution.

Choose stainless steel if you need the best rust protection and want it to last a long time. It is perfect for tough places like near the sea, in chemical plants, or where it is very humid. Stainless steel does not rust, even if it gets scratched. This makes it good for food factories, hospitals, and buildings where being clean and looking nice is important.

Stainless steel is also very strong, so you can use it for big jobs like bridges and power towers. It looks shiny and nice, so it is good for things people will see. If you want to spend less on fixing and replacing things later, stainless steel is a smart buy. Many companies use it for metal casting, pump parts, and power lines because it is strong and lasts a long time.

Note: Stainless steel is best for hard jobs, places with lots of stress, and when you care about how things look and how long they last. It also helps the planet because you do not have to throw it away or fix it as much.

This guide can help you pick between galvanized steel vs stainless steel for your project:

Project Need / Condition | Choose Galvanized Steel | Choose Stainless Steel |

|---|---|---|

Budget-Friendly | ✅ | |

Moderate Corrosion Resistance | ✅ | |

Harsh/Marine Environment | ✅ | |

High Strength/Load-Bearing | ✅ | |

Minimal Maintenance | ✅ | |

Industrial/Functional Appearance | ✅ | |

Decorative/Polished Finish | ✅ | |

Short to Medium Lifespan | ✅ | |

Long-Term Investment | ✅ |

For common uses like fences, roofs, and car parts, galvanized steel is a cheap and smart pick.

For common uses in food factories, boats, and fancy building parts, stainless steel is the best for lasting a long time and looking good.

If you are not sure which material to use, JOC Machinery Co., Ltd. can help. They have many choices for metal casting and steel forging. Their team knows a lot about both galvanized steel and stainless steel for different jobs.

When you look at galvanized steel and stainless steel, they are very different. Stainless steel does not rust easily and lasts a long time. It works well even in hard places. Galvanized steel is cheaper at first but might need more fixing if it gets rusty. Check this table to help you choose:

Factor | Galvanized Steel | Stainless Steel |

|---|---|---|

Rust Resistance | Moderate | Superior |

Durability | Good | Excellent |

Cost | Lower | Higher |

Maintenance | Sometimes needed | Rarely needed |

Think about how much money you want to spend. Also, think about where you will use the steel and how long you want it to last. For metal casting or steel forging, JOC Machinery Co., Ltd. has both types for your project.

Galvanized steel has a zinc layer that helps stop rust. Stainless steel has chromium and nickel inside it. These make it stronger and better at fighting rust. Pick the one that fits your project and where you will use it.

Both types can be welded. But you need to be careful with galvanized steel. The zinc layer can make fumes when heated. Stainless steel is often welded for metal forging and pump or valve parts.

Stainless steel is best for tough outdoor places, like near the sea or chemicals. Galvanized steel works well for mild outdoor spots, such as fences or sheds. Choose the one that matches your weather and how much it will face.

Both types should be cleaned often. Galvanized steel needs more checks for rust or scratches. Stainless steel does not need much care because its layer fixes itself.

You can get many galvanized steel and stainless steel products at JOC Machinery Co., Ltd.. They also have metal forging and pump or valve parts. Their team can help you pick the best material for your job.

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com