Views: 0 Author: Site Editor Publish Time: 26-01-2026 Origin: Site

The global market size for investment casting was USD 19.02 billion in 2025. Manufacturers pick investment casting because it can make detailed shapes with smooth surfaces.

Investment casting uses a wax pattern to make metal parts. It helps create parts with complex shapes and smooth surfaces.

The process works very well. It has yield rates of 85% to 90%. This makes it cheaper for jobs that need high precision.

Investment casting is great for aerospace and medical devices. These industries need parts that are very accurate and work well.

Investment casting costs more at first. But it needs less extra work later. This saves time and money over time.

This method works best for small or medium parts. These parts usually weigh less than 20 pounds. It is not the fastest way to make parts.

First, workers make a wax pattern. They shape the wax to look just like the final part. Molds help them form the wax and keep every detail clear. Sometimes, they join wax patterns together to make a "tree." This lets them cast many parts at once. This step is important because the wax pattern decides the size and shape of the finished part.

After making the wax pattern, workers dip it in liquid ceramic. They cover the wax with many layers. Each layer dries before the next one goes on. This makes a strong ceramic shell around the wax. The shell must be thick enough to hold hot metal. It also needs to be thin enough to show small details. This shell helps make smooth surfaces and sharp edges on the final part.

When the ceramic shell is ready, workers heat it up. The heat melts and removes the wax inside. This leaves a hollow space shaped like the wax pattern. Lost wax casting helps make parts with tricky shapes. It also makes sure the final part is the right size. This step means less extra work is needed later. Workers fire the shell at high heat to make it stronger and to get rid of any wax left.

With the shell empty and strong, workers heat it again. Then they pour in the hot metal. Preheating helps the metal flow and fill the shell. The investment casting process can use many metals. These include stainless steel, carbon steel, alloy steel, aluminum alloys, copper-based alloys, nickel-based alloys, and titanium alloys. The hot metal fills the shell and takes the shape of the wax pattern. This process can make thin walls and smooth surfaces that are hard to get with other ways.

After the metal cools and gets hard, workers break the ceramic shell. This shows the new metal part. They cut off extra metal, like gates and risers. Workers clean, grind, or polish the part to make it look better. The investment casting process often makes parts that need little extra work. In factories, this method gets yield rates of about 85% to 90%. For very exact uses, like medical devices, the yield rate can go above 95%.

Note: The investment casting process is known for being very exact. The table below shows how its accuracy compares to sand casting:

Casting Type | Dimensional Tolerance |

|---|---|

±0.005 in/in (±0.125 mm per 25 mm) | |

Sand Casting | ±0.020–0.040 in/in (±0.5–1 mm per 25 mm) |

Sometimes, the casting process can have problems. Workers use special ways to stop these problems. For example, they control the pouring temperature and shell strength. This helps stop things like holes, cracks, or bad surfaces. The table below lists common problems and how workers fix them:

Defect | Causes | Mitigation Strategies |

|---|---|---|

Porosity | Trapped gases, poor venting | Make mold more open, pour at the right speed |

Cracking | Uneven cooling, weak shell | Cool evenly, use better shell material |

Shrinkage | Metal shrinks as it cools, bad gating design | Use feeders, fix gating system |

Surface Defects | Dirty molds, bad shell prep | Clean molds, use good shell materials |

Inclusions | Dirty metal, bad handling | Filter metal, keep melting area clean |

Misruns | Metal too cool, bad gating design | Pour hotter, fix gating system |

Cold Shuts | Metal too cool, poor mold design | Pour hotter, fix mold design |

Shell Deformation | Uneven heating, weak shell | Heat evenly, use strong shell materials |

Metal Penetration | Metal too hot, bad mold materials | Lower temperature, use better mold materials |

Veining | Mold grows, metal too hot | Use better sands, lower temperature |

The investment casting process lets workers make parts with tricky shapes, thin walls, and smooth finishes. This process is the best way to make detailed and exact metal parts.

Investment casting is different from other metal forming methods. This process gives special benefits that many industries like. The advantages of investment casting process are high precision, making complex shapes, using materials well, and making smooth and accurate surfaces.

Investment casting gives very good accuracy. Manufacturers can make parts that match the design with little error. Most parts do not need extra work after casting. This saves both time and money. Compared to sand casting and die casting, investment casting has tighter tolerances. The process often means no trimming or fixing is needed. This makes investment casting great for parts that must fit together just right.

Engineers use investment casting for parts with hard shapes. The process can make thin walls, sharp corners, and detailed inside features. Die casting works best for simple or medium shapes. Investment casting can make much more detailed designs. The table below shows how different casting methods handle shape complexity:

Casting Method | Complexity of Shapes | Suitable Applications |

|---|---|---|

Investment Casting | Excellent for complex geometries and fine details | High-performance items in smaller quantities |

Die Casting | Suitable for moderately complex shapes | Large quantities with good accuracy and surface polish |

Investment casting can make thin walls and tricky inside shapes.

Die casting cannot make shapes as detailed as investment casting.

This helps designers make parts that are lighter and stronger. Many industries use investment casting for parts that other methods cannot make.

Investment casting uses materials in a smart way. The process makes parts close to the final shape. This means less cutting or extra work is needed. Wax patterns can be recycled and used again. This lowers waste compared to sand casting, which uses molds only once and makes more trash. Investment casting also makes less scrap and saves energy because less metal needs to be melted again. These things make investment casting good for the environment and for saving money.

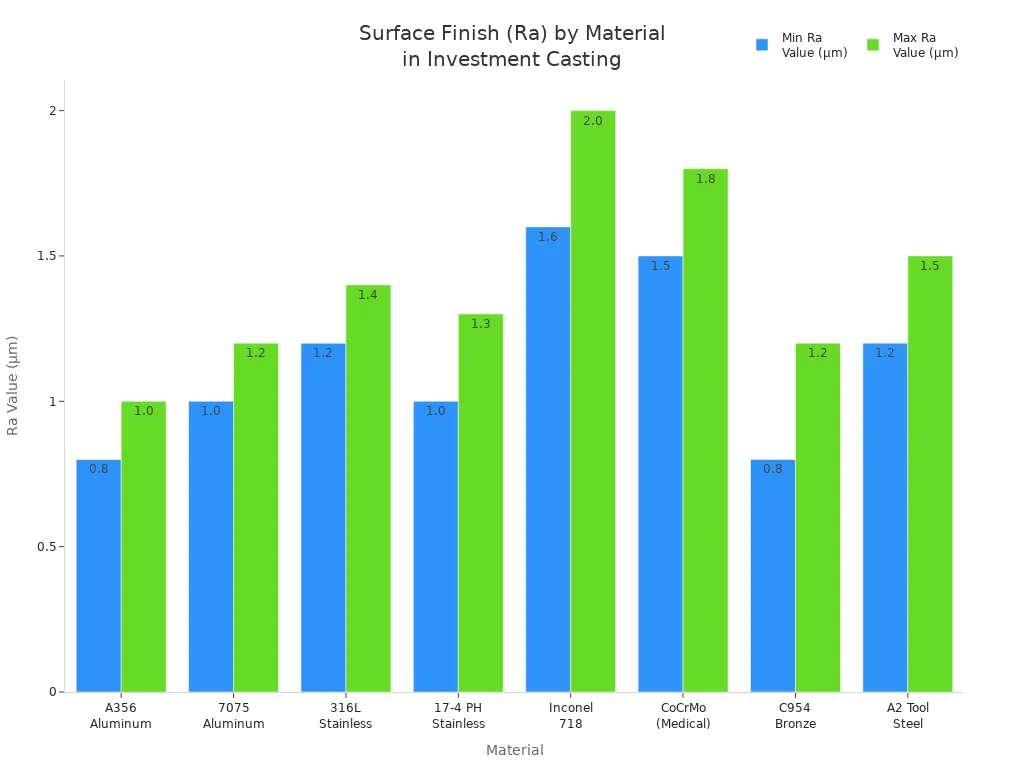

Parts made by investment casting have smooth and accurate surfaces. The ceramic shell copies every detail of the wax pattern. This gives a fine surface finish that often does not need more polishing. The table below shows the usual surface roughness (Ra value) for different materials:

Material | Ra Value (µm) | Notes |

|---|---|---|

A356 Aluminum | 0.8–1.0 | High fluidity → low porosity; fine dendritic structure |

7075 Aluminum | 1.0–1.2 | High shrinkage risk; needs good venting to stop hot tears |

316L Stainless | 1.2–1.4 | Passive oxide forms fast; thick film can make slight texture |

17-4 PH Stainless | 1.0–1.3 | Martensitic microstructure; heat treatment can fix surface defects |

Inconel 718 | 1.6–2.0 | High viscosity; slow fill can cause cold lash at thin spots |

CoCrMo (Medical) | 1.5–1.8 | Hard alloy; needs good shell to avoid grainy surface |

C954 Bronze | 0.8–1.2 | High fluidity, low melting → great detail and little grain ridging |

A2 Tool Steel | 1.2–1.5 | Tool steel can have carbide problems; shell must protect finish |

A fine surface finish means less time spent on grinding or polishing. This is important for industries that need parts to look clean or feel smooth.

Note: Investment casting works best for small to medium batch sizes. The process costs more at first than sand casting. But less work is needed later, so the total cost per part can be lower. The table below compares cost features:

Casting Type | Cost Characteristics |

|---|---|

Investment Casting | Higher upfront costs but lower total cost for precision parts. |

Sand Casting | More expensive per unit due to labor-intensive mold making. |

Investment casting gives high precision, makes complex shapes, uses materials well, and gives fine surface finishes. These features make it a top choice for many high-performance uses.

Investment casting has many good points, but it often costs more than other ways to cast metal. There are a few reasons for this higher price. If a part has a tricky shape, it needs a special mold. This makes the process cost more. When parts must be very exact, workers need special tools. Sometimes, they must do extra work after casting. The kind of metal used can also change the price. Some metals are expensive or need special care. After casting, workers might need to cut, shape, or heat the part. These steps add to the total cost. If a part needs a very smooth surface, workers must spend more time on the mold and polish the part. All these things make investment casting best for parts that need to be very exact or have special shapes. For simple parts or when making many at once, other casting ways can save money.

Investment casting is best for small and medium parts. Most factories make parts from one ounce up to about 20 pounds. Some places can make bigger parts, even up to 85 pounds or more. The table below shows the usual sizes:

Weight Range | Largest Dimensions |

|---|---|

1 oz – 85 lbs | 24” x 24” |

A few factories can make parts over 1000 pounds, but this does not happen often. Most parts are between a few ounces and 20 pounds. Very big parts can have problems with the mold being strong enough. They can also have trouble with the metal filling the mold right. Small parts, like dental braces, show how careful and exact investment casting can be.

Investment casting takes more time than some other ways to cast metal. There are many steps, like making wax shapes, building ceramic shells, and finishing the parts. Each step needs time and careful work. The table below shows how long it takes:

Casting Method | Production Lead Time Comparison |

|---|---|

Investment Casting | Generally longer due to multi-step ceramic shell process |

Sand Casting | More straightforward, quicker for larger components |

Because it takes longer, investment casting is not the best choice if you need parts very fast. But the extra time helps make sure each part is made well and has lots of detail.

Investment casting helps many industries make strong metal parts. These parts are exact and work well. This process is used when shapes are hard and need to last.

Aerospace engineers use investment casting for tough jobs. The parts must work in very hard places. The process makes parts that fit well and have smooth sides. Some aerospace uses are:

Turbine engine airfoils help air move better.

Fuel system parts like nozzles and pump impellers.

Exhaust and combustion parts made from metals that stand heat.

Engine pieces, hydraulic parts, and landing gear.

The table below shows why investment casting is good for aerospace:

Performance Benefit | Description |

|---|---|

High precision and tolerances | Parts fit well and have smooth sides. This keeps flights safe. |

Complex geometries | Makes tricky shapes. This helps parts weigh less and work better. |

Material flexibility | Uses many metals. This helps parts last in tough places. |

Reduced waste | Makes less scrap. This saves money and time. |

Medical device makers use investment casting for safe tools. The process uses metals that work well in the body. Some uses are:

Surgical tools and scalpels

Implants for knees, joints, and hips

Wheelchairs, stretchers, and tables for surgery

MRI and X-ray machine parts

Other items like pump housings and connectors

Investment casting makes sure medical parts are exact and work right.

Tip: Using safe metals and exact shapes helps medical tools work well.

Car makers pick investment casting for strong and light parts. The process makes thin parts with tricky shapes. Some car uses are:

Engine parts like cylinder heads and manifolds

Transmission gears, cases, and shafts

Suspension arms, knuckles, and steering parts

Brake calipers, rotors, and brackets

Fuel injectors, turbochargers, and trim

Investment casting helps cars weigh less. This saves gas and cuts pollution.

Factories use investment casting for tough parts. Some uses are:

Stainless steel pump impellers and valve bodies

Turbocharger cases and transmission gears

Hard alloys for machines that last longer than regular steel

Cobalt-chrome scalpels and titanium brackets for special jobs

Investment casting helps machines last longer and need less fixing. This saves money for companies.

Industries keep finding new ways to use investment casting. They want parts that work better and last longer.

Investment casting makes metal parts that are very exact. It can also make parts with hard shapes and smooth sides. New improvements use stronger metals and better ceramic shells. Smart machines help make the process faster and easier. Many industries use investment casting, like airplane and medical companies. Manufacturers like this method because it is very accurate. It can use many kinds of metals. It also helps save money. The table below explains why investment casting is special:

Benefit | Description |

|---|---|

Precision | |

Versatility | Works with many metals and shapes |

Sustainability | Uses recycled materials and eco-friendly methods |

Tip: Investment casting is a good way to make parts that need to be exact and have lots of detail.

Manufacturers use many metals for investment casting. Some common ones are stainless steel, aluminum alloys, bronze, and titanium. Each metal has its own strength and finish. Engineers choose the best metal for what the part needs to do.

Parts from investment casting are very accurate. Most parts match the design with only a small mistake. This process lets engineers make pieces that fit well and need little fixing.

Engineers use investment casting for parts with hard shapes. The process copies every detail from the wax pattern. Thin walls, sharp corners, and inside shapes come out clear and strong.

Factories mostly use investment casting for small or medium parts. Most parts weigh less than 20 pounds. Some places can make bigger parts, but very large ones may need other ways.

Many industries use investment casting. Aerospace, medical, car, and factory companies use it for strong and exact metal parts.

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com