Views: 0 Author: Site Editor Publish Time: 23-01-2026 Origin: Site

Pick the best casting method for your part. Think about how complex the part is. Also, think about how many you need and your budget. This helps you get good results.

Die casting works well when you need many parts. Investment casting is better for small batches with detailed shapes.

You can use new tools like 3D printing for molds. This helps make better parts and cuts down on waste.

Look at what materials you need and how fast you want to make parts. This helps you choose the right casting method and saves money.

Keep learning about new things in the industry. Watch for AI and green materials. This helps you make smart choices in casting.

There are more ways to make small metal parts now. In 2026, the main methods are die casting, investment casting, and metal injection molding. These ways are popular because they give you accurate parts, smooth surfaces, and the same results every time. Sand casting and centrifugal casting are also options for special jobs, but most people use the first three for small, tricky parts.

New machines, robots, and better alloys have changed metal casting. These changes help you work faster and make better parts. You can now make small parts that fit together well and look smooth. Many companies use 3D-printed molds. These molds last longer and handle heat better. This means your parts turn out the same each time and you waste less metal.

Trends in the industry affect what you pick. Here are some important things:

The car industry uses more steel casting.

Artificial intelligence helps you choose materials and make better parts.

Aluminum castings are used in cars and planes to make them lighter and save fuel.

Many companies care about the environment when picking materials.

Companies that make planes and machines want strong, cheap parts.

Big building projects around the world need more metal casting.

You can see these trends in how companies pick casting methods. You want a way that fits your part’s shape, material, and how many you need.

Die casting, investment casting, and metal injection molding are chosen because they fit today’s needs. These ways let you make small parts with special shapes, thin sides, and close fits. You also get faster work and lower costs, especially if you need lots of the same part.

Let’s see how new tech helps these methods:

Description of Advancement | Impact on Casting Methods |

|---|---|

3D printing makes stronger, better molds | You get higher quality and molds that last longer |

3D-printed molds spread heat well and do not crack easily | Your casting is more steady and works better |

New metal 3D printing materials make tough molds | Your molds last longer and do not wear out fast |

Conformal cooling keeps molds at the right temperature | You avoid hot spots and get the same results each time |

You should think about a few main things when picking a casting method:

Part Geometry & Complexity – If your part has thin sides or tiny details, you need a careful process like investment casting.

Material Requirements – Some alloys work best with certain casting ways.

Production Volume – Die casting is good for making lots of parts. Sand or investment casting is better for small amounts.

Budget & Lead Time – Think about how much tools cost, how much extra work is needed, and how fast you need your parts.

Functional Requirements – The strength, how long it lasts, and how smooth it is will help you decide.

Tip: Always pick a casting method that matches your part’s shape, material, and how many you need. This saves money and gives you the best results.

The best casting methods for small metal parts in 2026 use new technology, follow trends, and need good planning. When you know these things, you can make better choices for your projects.

You use investment casting when you need small parts with tricky shapes. This process helps you make parts with tiny details and smooth sides. First, you make a wax copy of your part. Then you cover the wax with a hard ceramic shell. When the shell is hard, you melt out the wax. Next, you pour hot metal into the empty shell. Investment casting works for gears, machine parts, and jewelry. You get very exact parts and nice finishes. But investment casting costs more and takes more time than other ways. The molds do not last long. So, you use investment casting for small batches or special shapes.

Key Features | Limitations |

|---|---|

High precision | Higher cost |

Excellent surface finish | Longer production cycle |

Capability for complex geometries | High design requirements |

Material flexibility | Mold durability is limited |

Reduced material waste |

Die casting is one of the fastest ways to cast metal. You push hot metal into a steel mold using high pressure. This gives you parts that fit together well and have smooth sides. Die casting works best for metals like aluminum and zinc. You can make thousands of parts fast. The machines and molds cost a lot at first. But you save money if you need many parts. Die casting is good for car parts, electronics, and tools. You get strong parts, but you cannot use every kind of metal.

Fast production speed and high productivity

High dimensional accuracy and smooth surface finish

High initial costs for machines and molds

Limited to non-ferrous metals

Sand casting is the oldest way to cast metal. You pack sand around a shape to make a mold. Then you pour hot metal into the sand mold. When the metal cools, you break the sand to get your part. Sand casting is cheap and flexible. You can use almost any metal. You can also change your part’s shape easily. Sand casting works for both small and big parts. You use sand casting when you want low cost and do not need a perfect finish. Sand molds are easy to make, but you get only okay detail.

Low cost in small volumes

Not limited by size

Easy to change part design

Sand molds are single-use

Centrifugal casting uses spinning molds to shape metal. You pour hot metal into a mold that spins fast. The spinning pushes the metal to the mold’s sides. This makes strong parts with few mistakes. Centrifugal casting is good for pipes, rings, and bushings. You save metal because the parts are close to the right shape. You can use many kinds of alloys. Centrifugal casting is not too expensive and gives steady results. You use this way when you need strong, round parts.

Complex geometry possible

Material savings and lower costs

Improved strength and durability

Versatile for many alloys

Metal injection molding mixes plastic injection molding with powder metallurgy. You mix metal powder with a binder to make a feedstock. You push this feedstock into a mold. After shaping, you take out the binder and heat the part. Metal injection molding lets you make small, exact parts with tricky shapes. You use it for electronics, dental tools, and medical devices. Metal injection molding is great for making lots of parts with tight fits. You get strong parts and do not waste much metal. It costs a lot to start and takes time, but it is worth it for big jobs.

Note: Metal injection molding is best for small, detailed parts like smartphone pieces, dental implants, and tiny gears.

You follow several steps in the investment casting process to create small metal parts with fine detail.

You start by making a wax pattern that matches your part.

You attach these wax patterns to a central wax rod, forming what people call a "tree."

You dip the tree into a ceramic slurry and sprinkle it with sand. This builds a hard shell around the wax.

You place the shell in a steam chamber to melt out the wax, leaving a hollow ceramic mold.

You heat the mold and pour in molten metal.

You break away the ceramic shell, cut off the gates, and finish the part.

This casting process gives you high accuracy and smooth surfaces.

The die casting process uses high pressure to fill a steel mold with molten metal. Each step affects the quality of your part.

Step | What It Means for Your Part |

|---|---|

Die Preparation | You get a clean, smooth surface. |

Metal Melting | You keep the metal at the right temperature. |

High-Pressure Injection | You fill the mold quickly and avoid defects. |

Cooling and Solidification | You control shrinkage and warping. |

Ejection | You remove the part without damage. |

Trimming | You cut off extra material for a perfect fit. |

You use this casting process for fast, repeatable results.

Sand casting uses a simple method. You pack sand around a pattern to make a mold. You pour molten metal into the mold. When the metal cools, you break the sand mold to get your part. You can use this casting process for many shapes and metals. Sand casting works well for prototypes and small batches.

You use centrifugal casting when you need strong, round parts.

You clean and coat the mold with a special material.

You pour molten metal into the spinning mold.

The spinning pushes the metal to the mold’s edge.

You keep the mold spinning until the metal hardens.

You open the mold and remove the finished part.

You must watch the temperature and cooling to avoid defects.

Metal injection molding combines powder metallurgy and plastic injection.

Step | Description |

|---|---|

Feedstock Preparation | You mix fine metal powder with a binder to make a soft feedstock. |

Injection | You inject the feedstock into a mold to form the part’s shape. |

Debinding | You remove the binder, leaving a fragile “brown part.” |

Sintering | You heat the part so the metal particles bond and shrink to final size. |

Post-Processing | You machine or treat the part for extra strength or tight tolerances. |

You must control shrinkage and wall thickness in metal injection molding. You also design draft angles for easy removal. Metal injection molding lets you make complex shapes with little waste. You use metal injection molding for electronics, dental tools, and small gears. Metal injection molding gives you strong, precise parts. Metal injection molding works best for high-volume production. Metal injection molding helps you save material and lower costs.

When you compare casting methods, you want to know two things. How much does each process cost? How fast do you get your parts? Here is a table that shows the main differences:

Casting Method | Upfront Tooling Cost | Tooling Maintenance Cost | Post-Cast Machining Costs | Total Labor Costs | Total Lead Time | Best Production Run Size |

|---|---|---|---|---|---|---|

Investment Casting | Medium to High | Low | Low | Medium to High | Long | Medium to Long |

Sand Casting | Medium | Low to Medium | Low to Medium | Medium | Medium | Low to Medium |

Centrifugal Casting | Zero to Low | Typically None | Medium to High | Medium | Short | All |

Die Casting | High | Medium | Low | Low | Short | High |

Metal Injection Molding | High | Medium | Low | Medium | Medium | High |

Die casting and metal injection molding are best for making lots of parts. Sand casting and centrifugal casting are better for small or medium amounts. Investment casting makes detailed parts but takes more time.

Surface finish and accuracy are important if you want parts that fit well. Here is a table that compares these things:

Casting Method | Surface Finish (RMS) | Dimensional Accuracy | Tolerance Level |

|---|---|---|---|

Investment Casting | Ra 1.5–3.2 µm | ±0.1% of length | Tight |

Sand Casting | Ra 6.3–25 µm | IT13 to IT16 | Loose |

Die Casting | Up to 20 RMS | IT6 to IT8 | Tight |

Centrifugal Casting | Poor | Fair | Medium |

Metal Injection Molding | Excellent | High dimensional accuracy | Very tight |

Investment casting, die casting, and metal injection molding give you smooth parts. They also make parts that are the right size. Sand casting gives rougher parts and looser fits.

You should also think about what shapes and metals you can use. Pick a process that lets you use the metal you want. You also want to make the shapes you need.

Casting Method | Design Freedom | Material Accommodation |

|---|---|---|

Investment Casting | Highly intricate, precise components | Wide range of metals |

Sand Casting | Complex geometries, thin walls | Various metals and alloys |

Die Casting | Good for thin walls, repeatable shapes | Non-ferrous metals |

Centrifugal Casting | Limited to round shapes | Many alloys |

Metal Injection Molding | Extreme design freedom | Many metals, especially for small parts |

Investment casting and metal injection molding let you make the most shapes. Sand casting is also good for tricky shapes.

You need to pick a casting method that matches how many parts you want. Here is a quick comparison:

Die casting and metal injection molding are best for lots of parts.

Investment casting is good for medium or long runs.

Sand casting and centrifugal casting work for small or medium amounts.

Tip: Always check how many parts you need before you choose a casting method. This helps you save money and get the right quality.

Comparing casting methods helps you pick the best one for your project. Here are some common uses:

Investment casting: gears, medical tools, jewelry

Die casting: car parts, electronics, tools

Sand casting: prototypes, machine bases, art pieces

Centrifugal casting: pipes, rings, bushings

Metal injection molding: dental implants, smartphone parts, tiny gears

You can use casting for many ways to make metal parts. Each casting method gives you different quality, fit, and design choices. When you compare casting methods, you see which one works best for your needs.

Investment casting helps you make small parts with tricky shapes. You can create thin walls and detailed designs. This method gives smooth surfaces and close fits. Your parts will fit together well. You can use many metals and waste less material. Tooling costs are lower than die casting, so you save money on small batches.

But investment casting costs more than sand casting. The process has many steps, so mistakes can happen. You cannot make big or heavy parts with this method. If you do not use machines, each part costs more.

Tip: Pick investment casting for small, detailed parts that need to fit well.

Die casting is good for making lots of parts fast. You get smooth surfaces and strong parts. This method keeps sizes steady and copies designs easily.

Pros | Cons |

|---|---|

Fast production | High mold costs |

Smooth surface finish | Size limits |

Strong parts | Only some metals |

Steady sizes |

Molds cost a lot at the start. Die casting works best for non-ferrous metals. You cannot make very big parts.

Sand casting is cheap and flexible. You can use many metals and make different shapes. The process is simple and quick. Tooling is cheap, so it is good for small jobs.

Benefits of Sand Casting | Drawbacks of Sand Casting |

|---|---|

Many shapes possible | Parts may be weak |

Many metals | Sizes may not be exact |

Cheap tooling | Rough surfaces |

Quick to make | Defects like shrinking |

You may need to fix the surface after casting. Parts may not be very strong. You can see defects or shrinking.

Centrifugal casting makes strong, round parts. You get good strength and can use many alloys. This method makes parts close to the right shape, so you waste less.

Strengths | Weaknesses |

|---|---|

Strong parts | Tooling costs more |

Close to final shape | Inner diameter not made |

Many alloys | Not for every size |

Tooling costs more. You cannot make every size. You cannot form the inner diameter with this method.

Metal injection molding makes small, detailed parts in large amounts. You get accurate sizes and smooth surfaces. This process uses less material and works for tricky shapes. You can use many metals for different needs.

But starting costs are high. The process takes longer and needs special machines. This method is best for lots of small parts with close fits.

Note: Use metal injection molding for many tiny, detailed parts.

You need to pick a casting method that matches your part’s shape. Some ways work better for simple parts. Other ways are good for tricky shapes. Look at this table to help you choose:

Casting Method | Complexity Suitability | Key Features |

|---|---|---|

Die Casting | Good for detailed designs because it is very exact. | Uses high pressure, makes fine details, and works well for big batches. |

Investment Casting | Best for very complex shapes and tiny details. | Uses wax patterns, copies undercuts and small designs, great for exact parts. |

Sand Casting | Works for medium complexity and many shapes. | Makes pretty complex shapes, but not as exact as die or investment casting. |

Gravity Casting | Best for simple or medium shapes, not for tiny details. | Fills slowly, walls stay even, good for less fancy designs. |

If your part is small and has a hard shape, use investment casting or die casting. Sand casting is fine for less detailed parts. Gravity casting is best for simple shapes.

Think about how many parts you need and how much you can spend. If you need a lot of parts, die casting or metal injection molding is best. These ways make each part cheaper when you make many. For small amounts, sand casting or investment casting saves money.

Die casting and metal injection molding: Best for making lots of parts with steady quality.

Sand casting: Good for testing ideas or making a few parts.

Investment casting: Great for medium batches with lots of detail.

Pick the way that fits how many parts you need. This helps you save money and reach your goals.

You want strong parts that do not break, but you do not want to spend too much. Here are some tips to help you:

Do not pick the cheapest way if you want your parts to last.

Use better metals, even if they cost more at first. This can save money later.

Work with a foundry that makes good parts.

Think about the total cost for the part’s whole life, not just the price to make it.

Remember extra steps like heat treatment or special finishes.

Sometimes, a lighter metal costs more but saves money when you use it, like aluminum in cars.

Tip: Always check both quality and cost before you pick a casting method. This helps you get the best results for your project.

You can find the right balance by thinking about how many parts you need, your budget, and how you will use the parts.

You can pick the best casting method by thinking about your part’s shape, how many you want, and how much you can spend. Die casting, investment casting, and metal injection molding help you make strong, good metal parts. It is smart to talk to experts or make a sample part first. Use this guide to look at your choices and choose the best way for your project.

You should choose investment casting or metal injection molding. These methods give you high detail and smooth surfaces. They work well for small parts with complex shapes.

You need to look at part shape, size, material, and how many parts you want. You should also think about your budget and how fast you need the parts.

No. Some methods only work with certain metals. For example, die casting works best with aluminum or zinc. Sand casting and investment casting let you use more types of metals.

3D printing lets you make strong, detailed molds quickly. You get better quality and less waste. You can also test new designs faster.

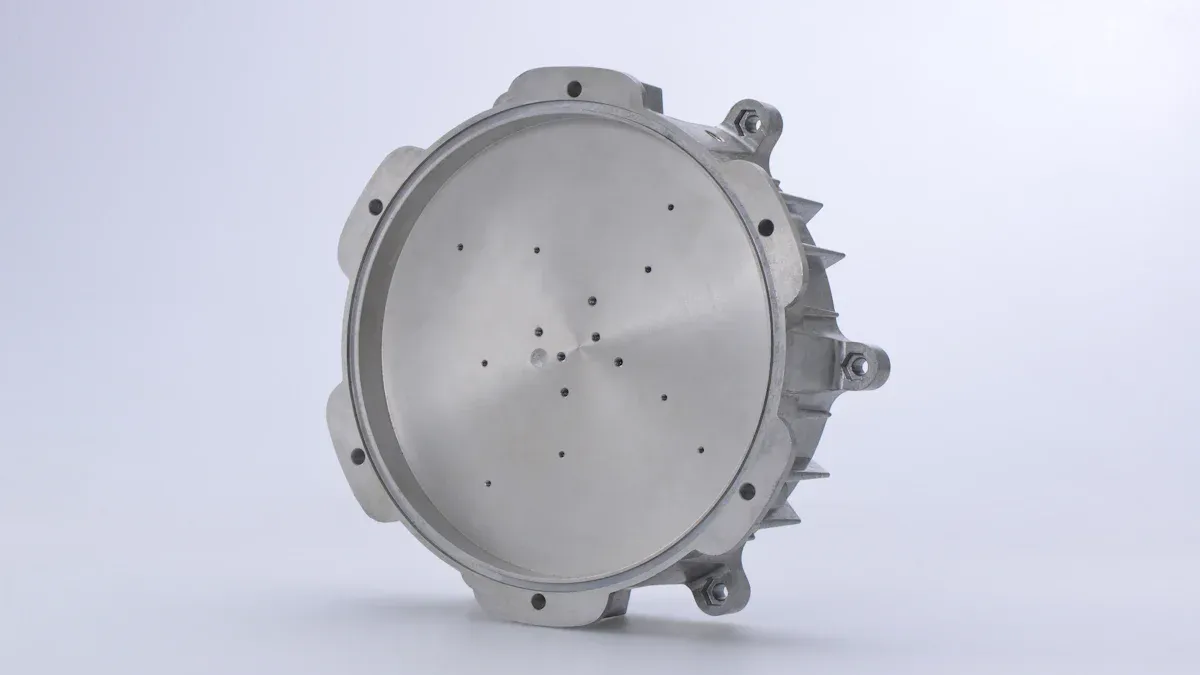

Our OEM Stainless Steel/Brass CNC Machining Mid-Size Pneumatic Valve Body is engineered for precise flow control in pneumatic systems used across industrial automation, energy, and manufacturing sectors. Manufactured in Jiangsu, China, this valve body is available in premium stainless steel or brass to suit different environmental and performance requirements. With ±0.05 mm tolerance, every component meets stringent quality standards for durability and operational reliability.

The CB310 Custom Slewing Drive is engineered for solar power tracking systems and other industrial applications that require smooth, precise rotational control. Designed and manufactured in Jiangsu, China, this slewing drive integrates a single-row cross roller bearing for maximum stability, and is compatible with either DC motors or hydraulic motors, depending on your project requirements. With diameters ranging from 200 mm to 4000 mm, this drive is suitable for a wide range of solar panel arrays and mechanical systems.

Add: 20/FL., 26 North Zhongshan Road, Nanjing, Jiangsu, China

Tel: 0086-25-83317070

Fax: 0086-25-83303377

E-mail: peter@jocmachinery.com