Construction Machinery Parts: Long-Life Hydraulic/Structural Parts

Welcome to explore JOC Machinery’s Construction Machinery Parts! We cover excavators, loaders, cranes, and focus on wear-resistant chassis, buckets, hydraulic parts—ideal for mining, heavy-duty work. Custom solutions and in-stock supply are available, bringing reliable performance to your projects.

Products Introduce

JOC Machinery’s Construction Machinery Parts are built for harsh construction environments, fitting excavators, loaders, and cranes to cut downtime from wear, shock, or corrosion. Our key components include wear-resistant buckets (high-manganese steel + heat-treated boron steel, hardness ≥ HRC55), undercarriage parts (rubber track pads), leak-proof hydraulic fittings, and specialized wear parts (e.g., alloy steel crusher hammers). With 30%-50% longer life than standard carbon steel, 1000+ hours salt spray resistance for coastal sites, and batch interchangeability, they suit mining (reinforced parts), coastal (corrosion-resistant) and urban (quiet track pads) projects. We offer in-stock standard parts (48-hour delivery) and custom solutions (72-hour quoting from drawings) for all scales.

Product Center

Product Advantages

To clearly highlight the core competitiveness of JOC Machinery’s Construction Machinery Parts, we summarize its advantages around two key dimensions that matter most to construction operations:

Superior Material & Performance (Long-Lasting Reliability)

JOC’s Construction Machinery Parts stand out with durability-focused designs: Made of high-manganese steel (shock resistance) and heat-treated boron steel (cutting edge hardness ≥ HRC55), they offer 30%-50% longer service life than standard carbon steel parts. For harsh environments, special protective coatings pass 1000+ hours of salt spray testing (ideal for coastal/chemical sites), while dimensional jigs ensure batch interchangeability—parts can be directly replaced without reworking, cutting maintenance time.

Scenario Adaptability & Flexible Supply

Tailored to diverse construction needs: Reinforced parts for mining/heavy-duty work, corrosion-resistant components for coastal projects, and quiet rubber track pads for urban infrastructure (protecting roads). Supply is equally flexible: Standard parts (e.g., track pads, buckets) are in-stock for 48-hour delivery, and custom solutions (via drawings) come with 72-hour quick quoting—supporting both small batches and large-scale project demands.

Technical Specifications

To provide clear, actionable performance references for your equipment matching and procurement decisions, the technical specifications of JOC Machinery’s Construction Machinery Parts are detailed below from three core dimensions—material performance, dimensional precision, and working condition adaptability—covering key indicators that directly affect part durability and compatibility:

Material Performance Parameters

Wear-Resistant Materials: Cutting edges and bucket bodies use heat-treated boron steel (hardness ≥ HRC55) and high-manganese steel (Mn content: 11%-14%), with impact toughness ≥ 18J/cm² (at -40℃) for resistance to crushing and deformation. Corrosion-Resistant Coatings: Components for coastal/chemical scenarios adopt epoxy zinc-rich primer + polyurethane topcoat, with coating thickness 80-120μm; salt spray resistance ≥ 1000 hours (per ASTM B117 standard), no rust or peeling. Hydraulic Component Materials: Hydraulic fittings are made of 304 stainless steel (for low-corrosion environments) or carbon steel with chrome plating (surface hardness ≥ HV800), ensuring pressure resistance up to 35MPa without leakage.

Dimensional & Precision Standards

Interchangeability Tolerance: Key components (e.g., undercarriage rollers, cutting edges) follow ISO 8062 H9 tolerance grade; batch size deviation ≤ ±0.3mm, enabling direct replacement without on-site reworking. Structural Fabrication Precision: Welded parts (e.g., bucket frames) use robotic welding (welding seam height ≥ 5mm) + NDT ultrasonic testing (no internal defects ≥ φ3mm); 3D scanning fitting accuracy ≤ 0.5mm, matching original equipment dimensions. Standard Part Sizes: Common products cover mainstream specifications—rubber track pads (e.g., 250×70mm, 300×80mm), hydraulic connectors (1/2" to 2" NPT threads), and crusher hammers (weight range: 5kg-50kg) for immediate compatibility.

Working Condition Adaptation Parameters

Load-Bearing Capacity: Mining-specific reinforced buckets can withstand maximum impact loads up to 80kN; undercarriage parts (e.g., track links) have static load capacity ≥ 300kN, suitable for heavy-duty operations like ore loading. Temperature & Environmental Adaptability: Parts maintain performance in -30℃ to 80℃ ambient temperature; rubber components (e.g., track pads) use EPDM rubber (aging resistance: ≥ 5 years outdoors), avoiding hardening or cracking in extreme weather. Noise & Road Protection: Urban-use rubber track pads have a noise level ≤ 75dB (at 5km/h), 15dB lower than steel tracks; surface anti-slip patterns (depth ≥ 3mm) prevent skidding while protecting asphalt/cement roads from scratches.

Application

Contact Us

Whether you have needs for mining-specific wear parts, coastal corrosion-resistant components, municipal project quick-delivery parts, or customized solutions for special engineering—we’re ready to provide tailored support for your Construction Machinery Parts procurement and matching. To get exclusive quotes, technical parameter details, or one-on-one solution consultations, feel free to reach out via the following channels:

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- JOC line hardware.pdf

- Uncategorized

- 2025-10-22

- 2.85MB

- 89

-

- Download

- Copy Link

- Automatic Shelling Robot_ Octopus_Brochure.pdf

- Automatic Shelling Robot_ Octopus_Brochure

- Uncategorized

- 2023-11-16

- 1.03MB

- 177

-

- Download

- Copy Link

- Automatic shelling video.mov

- Automatic shelling video

- Uncategorized

- 2023-05-10

- 47.54MB

- 189

-

- Download

- Copy Link

- Automatic shelling video.rar

- Automatic shelling video

- Uncategorized

- 2022-12-08

- 47.46MB

- 118

-

- Download

- Copy Link

- Automatic Shelling OCTOPUS* Instructions

- Automatic Shelling OCTOPUS* Instructions

- Uncategorized

- 2022-11-29

- 743KB

- 198

-

- Download

- Copy Link

- JOC Catalogue for Petroleum Machinery(Revised).pdf

- Uncategorized

- 2022-05-10

- 1.20MB

- 175

-

- Download

- Copy Link

- JOC Catalogue for Cable machinery.pdf

- Uncategorized

- 2022-05-10

- 1.54MB

- 174

-

- Download

- Copy Link

- Catalogue for Optical cable and material.pdf

- Uncategorized

- 2022-05-10

- 936KB

- 168

-

- Download

- Copy Link

- Transmission&Distirbution Catalog.pdf

- Uncategorized

- 2022-04-29

- 2.81MB

- 185

-

- Download

- Copy Link

- Comprehensive Catalog.docx

- Uncategorized

- 2021-07-14

- 13.48MB

- 236

-

- Download

- Copy Link

FAQs

Our Certificate

To ensure our Construction Machinery Parts meet strict quality/performance standards for mining, coastal, and urban scenarios, we hold authoritative certifications. Covering material compliance, manufacturing processes, and performance testing, these certifications validate the parts’ durability, precision, and reliability. Key certifications include:

Related Blogs

-

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News -

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News -

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News -

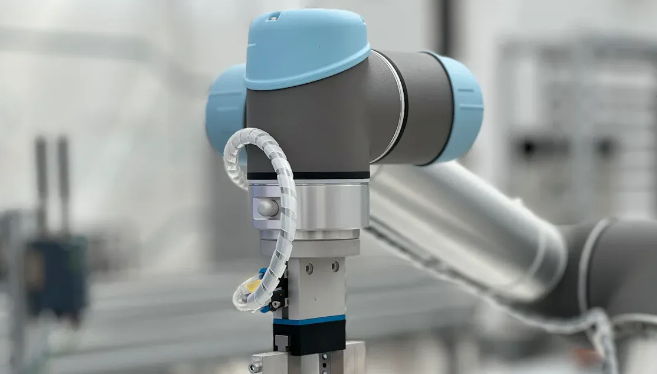

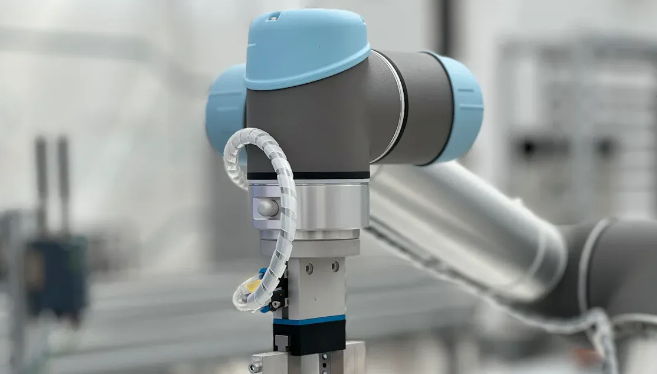

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

Keep In Touch With Us

Whether you need to consult about parts for mining/coastal/urban projects, inquire about custom solutions, or get technical support—we’re ready to connect with you. To share your procurement needs or stay updated on our Construction Machinery Parts:

Mob:0086-25-83317070

E-mail:peter@jocmachinery.com