JOC Machinery Industrial Materials: Multi-category Customized Supply

Welcome to learn about JOC Machinery Industrial Materials! Covering metal alloys, engineering plastics, specialty materials and more, we support on-demand customization with stable supply and professional technical support—feel free to inquire if you have needs!

Products Introduce

JOC Machinery’s Industrial Materials covers high-quality options like metal alloys (carbon steel, aluminum alloys, nickel-based 713LC for engines, tinned/galvanized steel tapes), engineering plastics & composites (silicone rubber, PET tapes, cable-specific water-blocking yarn), and specialty chemicals & coatings. We offer ready-stock standards and on-demand customization—with 7-15 day lead times for specialty materials (faster than the industry’s 20 days) and 5 strict inspections to keep defect rates below 0.3% (lower than the 0.5-1% industry average). Supported by free TDS and professional advice, our materials serve automotive components, optical cable shielding, new energy, and high-end manufacturing, delivering stable, reliable solutions.

Product Center

Product Advantages

JOC Machinery Industrial Materials excels with two core advantages, focusing on supply efficiency and quality reliability.

Product & Supply Resilience

We cover a full range of high-quality industrial materials, including metal alloys (e.g., carbon steel, nickel-based 713LC), engineering plastics & composites (e.g., silicone rubber, cable-specific water-blocking yarn), and specialty chemicals. Both ready-stock standard products and on-demand customization are available—with a 7-15 day lead time for specialty materials, outperforming the industry’s average 20-day response, to meet diverse urgent or tailored needs.

Quality & Technical Assurance

All materials undergo 5 strict inspections, keeping the defect rate below 0.3% (lower than the 0.5-1% industry average) for reliable performance. We also provide free Technical Data Sheets (TDS) and professional process advice, helping customers optimize material application in scenarios like automotive components, optical cables, and new energy equipment, ensuring smooth production.

Technical Specifications

JOC Machinery Industrial Materials’ technical specifications focus on its core categories—metal alloys, engineering plastics & composites, and specialty chemicals & coatings—covering key performance and quality metrics.

Metal Alloys Specifications

Key variants include carbon steel (tensile strength 400-600 MPa, elongation ≥15%), aluminum alloys (e.g., 7075-T6 with hardness 150-160 HB, corrosion resistance compliant with ASTM B209), and nickel-based 713LC alloy (operating temperature up to 950℃, creep resistance meeting AMS 5383). Tinned/galvanized steel tapes feature a coating thickness of 5-20 μm, adhesion strength ≥30 N/cm, and are suitable for optical cable shielding and steel wire carrier applications.

Engineering Plastics & Composites Specifications

Silicone rubber composites offer a temperature resistance range of -60℃ to 250℃, shore hardness 50-80 A, and water absorption rate ≤0.5% (24h immersion). PET tapes have a tensile strength ≥200 MPa, dielectric strength ≥25 kV/mm, and peel strength ≥10 N/25mm. Double semi-conductive layer water-blocking yarn (CZS type) achieves complete water blocking within 30 seconds of contact, with a breaking strength ≥500 N.

Specialty Chemicals & Coatings Specifications

Anti-oxidation coatings for cables have a dry film thickness of 20-50 μm, salt spray resistance ≥1000 hours, and compatibility with most metal/plastic substrates. Casting mold release agents feature a pH range of 6.5-7.5, volatilization rate ≤5% (100℃, 2h), and can reduce mold sticking rates by over 95%. All chemicals comply with RoHS and REACH environmental standards for safe industrial use.

Application

Contact Us

If you have needs for JOC Machinery Industrial Materials—whether it’s customizing metal alloys, inquiring about cable-specific water-blocking yarn, or seeking technical advice on material applications—feel free to reach out via the Contact Us section below.

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- JOC line hardware.pdf

- Uncategorized

- 2025-10-22

- 2.85MB

- 91

-

- Download

- Copy Link

- Automatic Shelling Robot_ Octopus_Brochure.pdf

- Automatic Shelling Robot_ Octopus_Brochure

- Uncategorized

- 2023-11-16

- 1.03MB

- 181

-

- Download

- Copy Link

- Automatic shelling video.mov

- Automatic shelling video

- Uncategorized

- 2023-05-10

- 47.54MB

- 192

-

- Download

- Copy Link

- Automatic shelling video.rar

- Automatic shelling video

- Uncategorized

- 2022-12-08

- 47.46MB

- 120

-

- Download

- Copy Link

- Automatic Shelling OCTOPUS* Instructions

- Automatic Shelling OCTOPUS* Instructions

- Uncategorized

- 2022-11-29

- 743KB

- 202

-

- Download

- Copy Link

- JOC Catalogue for Petroleum Machinery(Revised).pdf

- Uncategorized

- 2022-05-10

- 1.20MB

- 178

-

- Download

- Copy Link

- JOC Catalogue for Cable machinery.pdf

- Uncategorized

- 2022-05-10

- 1.54MB

- 177

-

- Download

- Copy Link

- Catalogue for Optical cable and material.pdf

- Uncategorized

- 2022-05-10

- 936KB

- 171

-

- Download

- Copy Link

- Transmission&Distirbution Catalog.pdf

- Uncategorized

- 2022-04-29

- 2.81MB

- 187

-

- Download

- Copy Link

- Comprehensive Catalog.docx

- Uncategorized

- 2021-07-14

- 13.48MB

- 238

-

- Download

- Copy Link

FAQs

Our Certificate

Backed by our commitment to quality (seen in strict inspections and industry-beating defect rates), JOC Machinery’s Industrial Materials have earned recognized certificates, which confirm our ability to meet rigorous standards for metal alloys, engineering plastics, and specialty chemicals.

Related Blogs

-

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News -

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News -

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News -

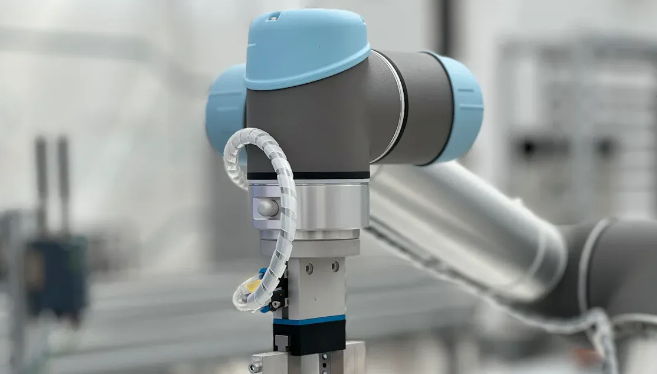

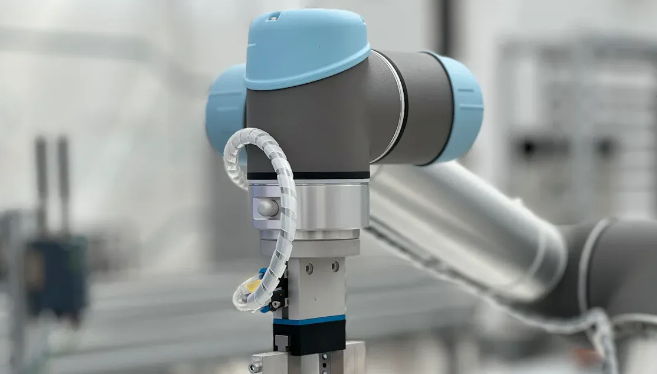

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

Keep In Touch With Us

Whether you need follow-ups on customization progress, latest quotes for new energy materials, or extra technical advice, keep in touch with us—JOC Machinery ensures smooth communication for your industrial material projects.

Mob:0086-25-83317070

E-mail:peter@jocmachinery.com