Long-Lasting Corrosion-Resistant Transmission Line Fittings: Covering Various Types of Accessories, Providing Hardware Support for Grid Power Transmission

Welcome to check out our Transmission Line Fittings! Made of multi-material options, produced to ISO standards, they prevent power outages and hot spots. Suitable for overhead lines and substations, they’re your solid hardware support for grid transmission.

Products Introduce

# Products Introduce JOC’s Transmission Line Fittings are reliable hardware for overhead power lines and substations, including fittings, clamps, connectors, brackets, and structural parts. We offer aluminum alloy, galvanized steel, and stainless steel options (selected by environment and load) for long-term use in harsh conditions. Made to ISO standards, our fittings have good conductivity, strong mechanical strength, and anti-corrosion performance—preventing hot spots and power outages to stabilize grids. Ideal for line upgrades or new substation builds.

Product Center

Product Advantages

Our Transmission Line Fittings stand out in the market with targeted advantages that directly address the core demands of overhead power lines and substations—focusing on both adaptability to diverse scenarios and reliability in long-term operation. Below are the key strengths that make our products a trusted choice for grid infrastructure:

Flexible Material Selection & Strong Environmental Adaptability

We offer three high-quality material options—aluminum alloy, galvanized steel, and stainless steel—carefully chosen based on actual application scenarios (such as humidity and corrosion risks) and load requirements. This targeted material matching ensures our fittings maintain long-term structural integrity and stability, even in harsh operating environments, fully meeting the diverse needs of overhead power lines and substations.

Excellent Performance & Rigorous Quality Assurance

All fittings boast core advantages of good conductivity (reducing energy loss), strong mechanical strength (withstanding external stresses), and long-lasting corrosion resistance. Manufactured strictly in line with ISO standards, our products undergo consistent quality control from production to delivery, effectively preventing grid issues like hot spots and unexpected power outages, and providing reliable support for stable and efficient grid operation.

Technical Specifications

To ensure our Transmission Line Fittings fully meet the rigorous requirements of overhead power lines and substations, we have defined clear, quantifiable technical specifications covering material properties, performance limits, and manufacturing standards. These detailed parameters not only guarantee product reliability but also help customers accurately match fittings to their specific application scenarios, as outlined below:

Material Specifications

Aluminum Alloy: Adopts high-purity aluminum alloy (e.g., 6061/6063 series), with tensile strength ≥ 205 MPa, yield strength ≥ 170 MPa, and elongation ≥ 8%. Lightweight (density ~2.7 g/cm³) and excellent in electrical conductivity (~50-60% IACS), suitable for medium-load, low-corrosion overhead line scenarios. Galvanized Steel: Uses hot-dip galvanized carbon steel (e.g., Q235/Q355), with galvanized layer thickness ≥ 85 μm. Tensile strength ≥ 375 MPa, yield strength ≥ 235 MPa, and superior rust resistance, ideal for high-load, outdoor harsh environments. Stainless Steel: Selects 304/316 stainless steel, with tensile strength ≥ 515 MPa, yield strength ≥ 205 MPa, and excellent corrosion resistance (resistant to acid, alkali, and salt spray). Suitable for coastal, high-humidity, or chemical-corrosion-prone substation areas.

Performance Parameters

Electrical Conductivity: For aluminum alloy and stainless steel fittings, the electrical resistivity ≤ 0.028 Ω·mm²/m at 20°C; galvanized steel fittings meet the conductivity requirements of power transmission hardware, ensuring minimal energy loss during current transmission. Mechanical Strength: All fittings pass load tests—clamps and connectors can withstand static load ≥ 90% of the rated breaking load of matched conductors; brackets and structural parts have a safety factor ≥ 2.5 against bending and torsion. Corrosion Resistance: Aluminum alloy fittings undergo anodizing treatment (film thickness ≥ 10 μm); galvanized steel fittings pass 500-hour salt spray test without red rust; stainless steel fittings pass 1000-hour salt spray test with no visible corrosion, ensuring a service life of ≥ 15 years.

Manufacturing & Certification Standards

Production Process: Strictly follows ISO 9001 quality management system, with key processes (e.g., forging, machining, surface treatment) controlled by automated equipment to ensure dimensional accuracy (tolerance ≤ ±0.1 mm for critical parts). Certifications: All products comply with international standards including ISO 4885 (for overhead line fittings) and IEC 61284 (for power transmission hardware). Each batch is accompanied by a test report covering material composition, mechanical performance, and corrosion resistance. Packaging Specifications: Uses moisture-proof cartons or wooden crates, with anti-collision foam inside. Each fitting is labeled with model, material, batch number, and production date for traceability.

Application

Contact Us

If you have inquiries about our Transmission Line Fittings—whether it’s details on material selection for specific application scenarios, technical specification verification, or customization needs for grid projects—our team is ready to provide professional support. Reach out to us through the following channels, and we will respond to your questions promptly to help you find the most suitable hardware solution for your power infrastructure:

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- JOC line hardware.pdf

- Uncategorized

- 2025-10-22

- 2.85MB

- 91

-

- Download

- Copy Link

- Automatic Shelling Robot_ Octopus_Brochure.pdf

- Automatic Shelling Robot_ Octopus_Brochure

- Uncategorized

- 2023-11-16

- 1.03MB

- 181

-

- Download

- Copy Link

- Automatic shelling video.mov

- Automatic shelling video

- Uncategorized

- 2023-05-10

- 47.54MB

- 192

-

- Download

- Copy Link

- Automatic shelling video.rar

- Automatic shelling video

- Uncategorized

- 2022-12-08

- 47.46MB

- 120

-

- Download

- Copy Link

- Automatic Shelling OCTOPUS* Instructions

- Automatic Shelling OCTOPUS* Instructions

- Uncategorized

- 2022-11-29

- 743KB

- 202

-

- Download

- Copy Link

- JOC Catalogue for Petroleum Machinery(Revised).pdf

- Uncategorized

- 2022-05-10

- 1.20MB

- 178

-

- Download

- Copy Link

- JOC Catalogue for Cable machinery.pdf

- Uncategorized

- 2022-05-10

- 1.54MB

- 177

-

- Download

- Copy Link

- Catalogue for Optical cable and material.pdf

- Uncategorized

- 2022-05-10

- 936KB

- 171

-

- Download

- Copy Link

- Transmission&Distirbution Catalog.pdf

- Uncategorized

- 2022-04-29

- 2.81MB

- 187

-

- Download

- Copy Link

- Comprehensive Catalog.docx

- Uncategorized

- 2021-07-14

- 13.48MB

- 239

-

- Download

- Copy Link

FAQs

Our Certificate

To ensure our Transmission Line Fittings meet global quality standards and reliable application requirements in power grid projects, we have obtained a series of authoritative certifications covering quality management, product performance, and industry compliance. These certifications not only validate the excellence of our products but also provide customers with solid assurance for safe and compliant use, as detailed below:

Related Blogs

-

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News

If you need new Rubber Tracks for a mini excavator, compact track loader, skid steer, or farm machine, one thing matters more than anything else: getting the measurements right. Measuring Rubber Tracks is simple when you know what to look for—width, pitch, guide type, and link count—and how to verify those numbers across different machines and wear levels. This guide gives you a quick, featured‑snippet‑style answer, an easy checklist, two data-driven tables, and practical troubleshooting so you can order with confidence and avoid downtime. You’ll also learn how those measurements tie into the undercarriage parts you should inspect or upgrade, including options across Agricultural Machinery Parts and related manufacturing categories you can source in one place.Industry News -

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News

Keeping an engine healthy starts with one habit: checking the oil correctly. The good news is you can do it in minutes with tools you already have. This guide gives you a quick, featured-snippet-ready answer, a step-by-step checklist, two handy comparison tables, and a plain‑English explanation of what your dipstick is telling you. Then, we connect the task to durable, leak-free oil system components you can upgrade through modern manufacturing—especially Metal Casting and Metal CNC Machining—using a single product hub so you can explore options or request a quote when you’re ready.Industry News -

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News

A sharp mower blade gives cleaner cuts, healthier grass, and faster mowing. If you’re standing in front of a grinder wondering what grit flap disc to use, here’s the quick, practical answer—and a complete guide that also connects what you learn to larger Disc Blade maintenance, including Harrow Disc Blade use in agriculture and other Agricultural Machinery Parts. You’ll find a quick answer, a comparison table for grits, simple steps, mistakes to avoid, and how to source or upgrade blades and related parts through a manufacturing partner.Industry News -

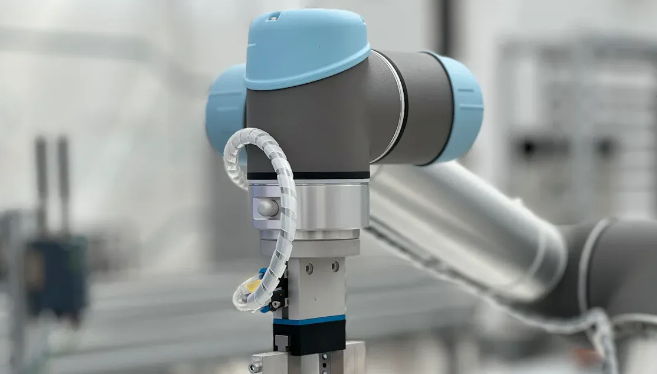

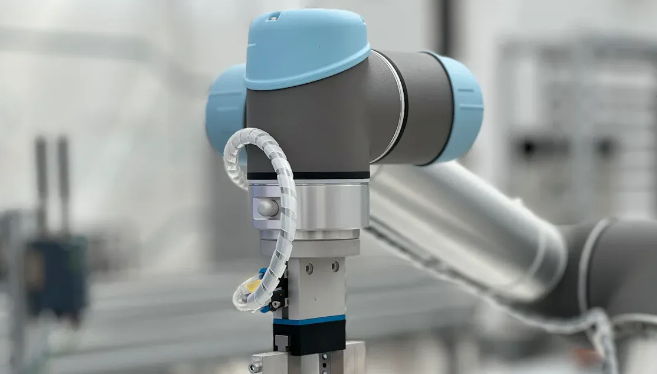

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

You make an extendable robot arm by planning its shape. You pick good materials for the arm. You build the extension part and put all pieces together. You test the finished robot arm to see if it works. Choosing the right parts helps the arm stay steady and reach far. Many beginners have trouble with making the robot arm exact. They also find it hard to set up and keep the arm stable. You can solve these problems by trying new designs. You learn from each try. The steps are easy to follow, even if you are new to robotics.Industry News

Keep In Touch With Us

Whether you have follow-up questions about Transmission Line Fittings (such as material details, application adaptation,or certification verification), or hope to discuss customized solutions for your grid projects, we welcome you to keep in touch with us. Maintaining close communication helps us better understand your needs and provide more targeted support for your power infrastructure construction or upgrade plans:

Mob:0086-25-83317070

E-mail:peter@jocmachinery.com